Home > Products > Casting & Forging > Hot Forging > Forging 4340 Outboard Long Motor Shaft/Steel Forging Shaft

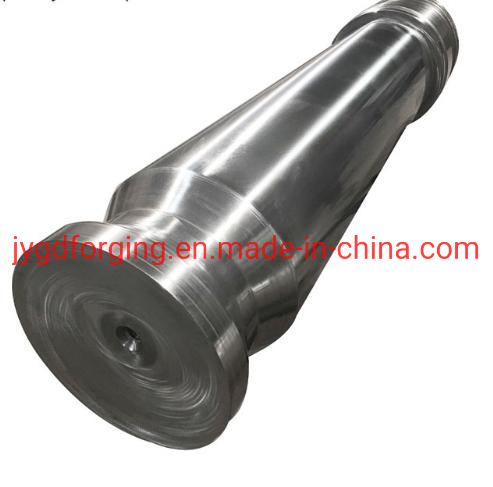

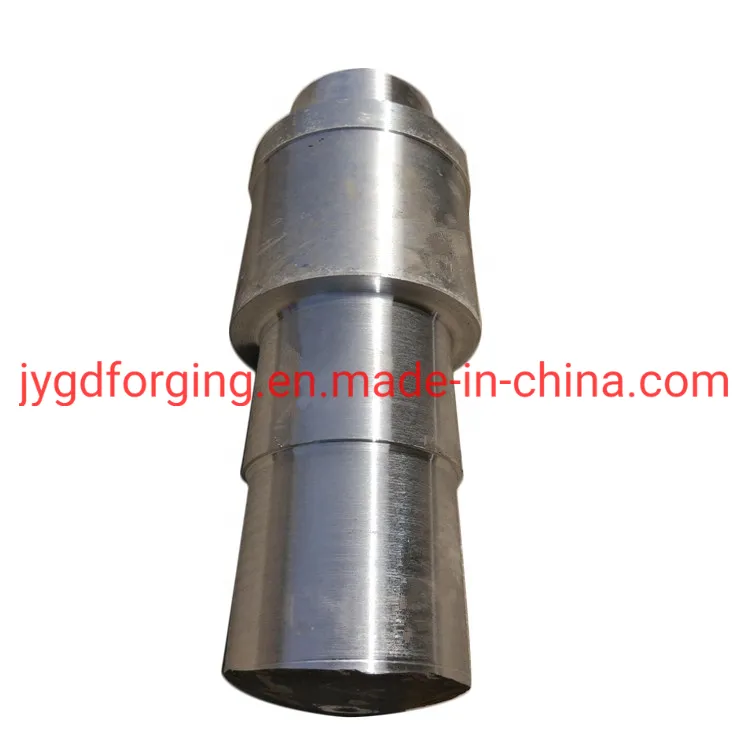

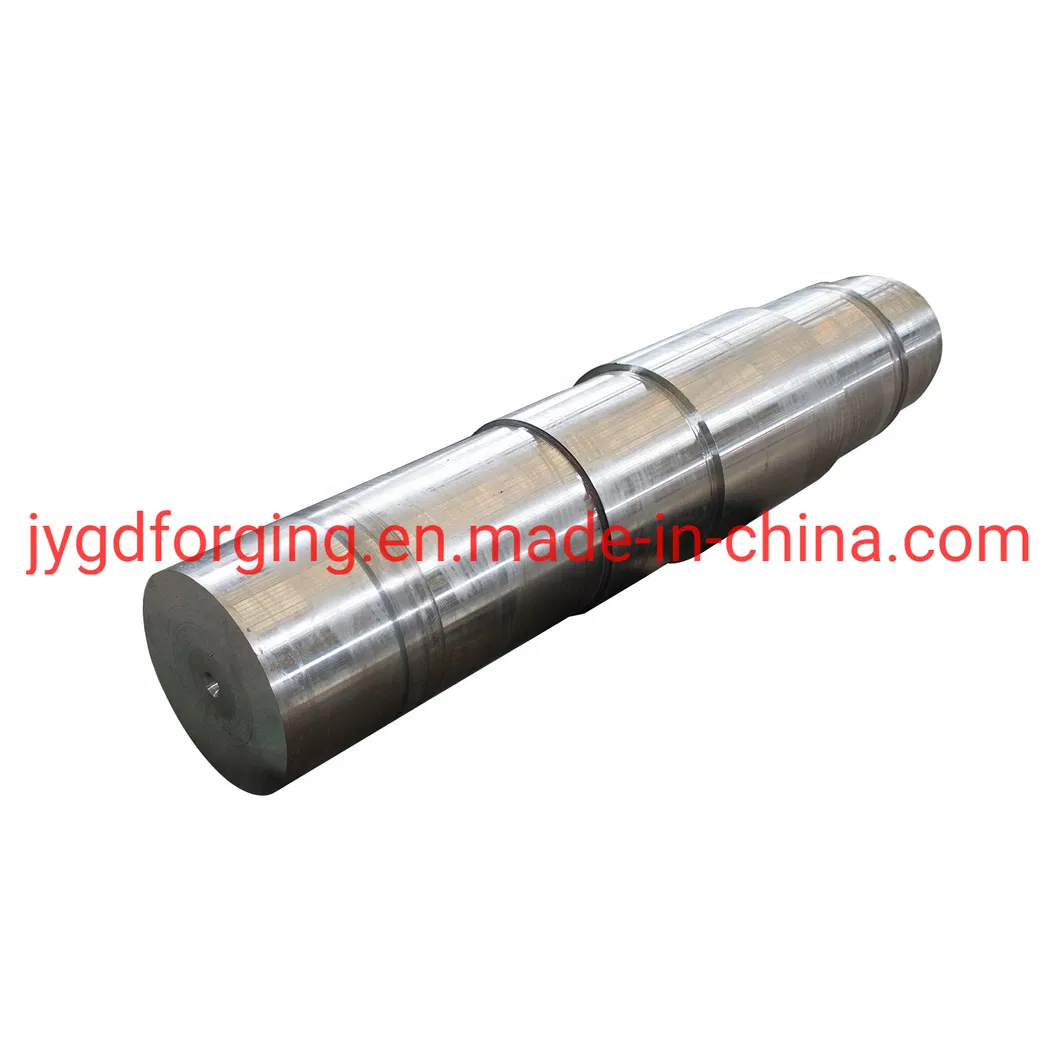

Forging 4340 Outboard Long Motor Shaft/Steel Forging Shaft

Name: Forging sae4140 scm440 A105 steel motor shaft /steel forging shaftWe are the manufacturer specialized in machining heavy duty forging parts for nearly 18 years.Our products, such as drive shaft, Forging Hollow Shaft, Shaft Sleeve, Eccentric shaft, Forging rod, Large bolt, Heavy Duty Hydraulic ......

Send Inquiry

Product Description

We are the manufacturer specialized in machining heavy duty forging parts for nearly 18 years.Our products, such as drive shaft, Forging Hollow Shaft, Shaft Sleeve, Eccentric shaft, Forging rod, Large bolt, Heavy Duty Hydraulic Cylinder, are widely used in coiled material, petroleum, metallurgy, mine, machinery and transportation industry. etc.

Packaging & Delivery

| Packaging Details: | Export standard package or according to customer requirement |

| Delivery Detail: | 30~60days according to various quantity |

Product List

| Name | Technique | Material | Dia/mm | Wall thickness | Length/mm |

| Forging shaft | Forging+turning+grinding | alloy steel carbon steel stainless steel | 200-800 | ---- | 500-20000 |

| Hollow shaft | Forging+drilling+turning | 150-800 | ≥15mm | ≤17000 | |

| Shaft sleeve | Forge+drill & bore+turning +milling | 400-700 | ≥15mm | ≤18000 | |

| Large bolt | Rolled/forge+turning+threading | 300-800 | ---- | ≤17000 | |

| Hydraulic cylinder | Forging+drill & bore+ turning | 300-2000 | ≥10mm | ≤10000 | |

| Other parts in deep-hole | Forge+ drill & bore+turning+mill | 300-2000 | ---- | ≤20000 |

Product Flow

1.Inquiry with drawings in details.

2.Confirm steel material, chemical compositions, mechanical properties, tolerance.

3.Confirm payment terms,order materials or check material in stock.

4.Check material chemical compositions, material weight, dimensions.

5.Cut materials record weight, making mould for casting of pr-hearting for forging.

6.Forging ratios, heat treatment ,dimension check.

7.Rough machining, UT test,heat treatment.

8.Semi-finish, quenching,

8.Fine machining, UT test, dimension inspection, mechanical properties test.

9.Customer inspection, packing, delivery arrangement.

Steel ingot making

EAF+LF+VD/VAD or ESR

Manufacturing process

EAF + LF + VD+ Forging+ Normalizing & Tempering + Rough machining + UT test + Quenching & Tempering + Precision machining

Report

Chemical composition report, Physical properties report, Heat treatment report, Dimensional inspection report, NDT report

Nondestructive test (NDT),UT ( ultrasonic testing ), MT ( magnetic particle testing ), PT ( penetrant testing)

Quality certification: ISO 9001: 2008, IQNET.

| Item | Process | Facility | Inspection items | Standard |

01 | Steel material inspection | Chemical composition (EF+LF+VD) | Material standard | |

| surface | Ingot inspection specification | |||

| Ingot type and weight | Material standard | |||

| 02 | Material store | Division put | warehouse management | |

| 1 | Heat | Heat furnace | Temperature/Time | Heating process specification Forging production procedure |

| 2 ↓ | Forging | Press | Reduction ratio,forging temperature,deformation, Surface and dimensions | Forging process card Forging procedure |

| 3 ↓ | Heat treatment | heat treatment furnace | heat treatment charts | 1st heat-treatment card Forging procedure |

| 4 ↓ | Rough inspection | Dimensions, apperance, Mark | Inspection specification Forging procedure | |

| 5 ↓ | Rough UT | UT equipment | Single defect, concentrated Defects bottom wave attenuation | UT standard or customer's technical requirements |

| 6 ↓ | Saw cutting | Saw machine | Dimension | IQC and forging |

| 7 ↓ | rough turning | turning-lathe | Dimension,appearance | Rough machining drawing |

| 8 ↓ | UT | UT equipment | Single defect, concentrated defects bottom wave attenuation | UT standard or customer's technical requirements |

| 9 ↓ | Q+T heat treatment | heat treatment furnace | heat treatment charts | Heating process specification |

| 10 ↓ | Sampling or machining | machining tool | rough machining drawing sampling drawing | sample machining drawing |

| 11 ↓ | mechanical property test | tensile testing machine/ impact testing machine | ambient temperature,humidity, Test temp.Sample dimension, test method | Standard technical specification |

| 12 ↓ | finish machining | machining tool | Dimension,appearance | finish machining drawing |

| 13 ↓ | UT | UT equipment | Single defect, concentrated Defects bottom wave attenuation | UT standard or customer's technical requirements |

| 14 ↓ | MT | MT equipment | Magnetic particle indication | Test standard or Technical requirements |

| 15 ↓ | Mark | Steel seal | marking content | Product standard Technical requirements Forging process |

| 16 ↓ | Final inspection | Appearance, dimension, mark acceptance inspection | Product inspection specification Product standard P.O. | |

| 17 | Protection/ package | Blasting Blasting equipment | appearance coating thickness | Product standard Technical requirements |

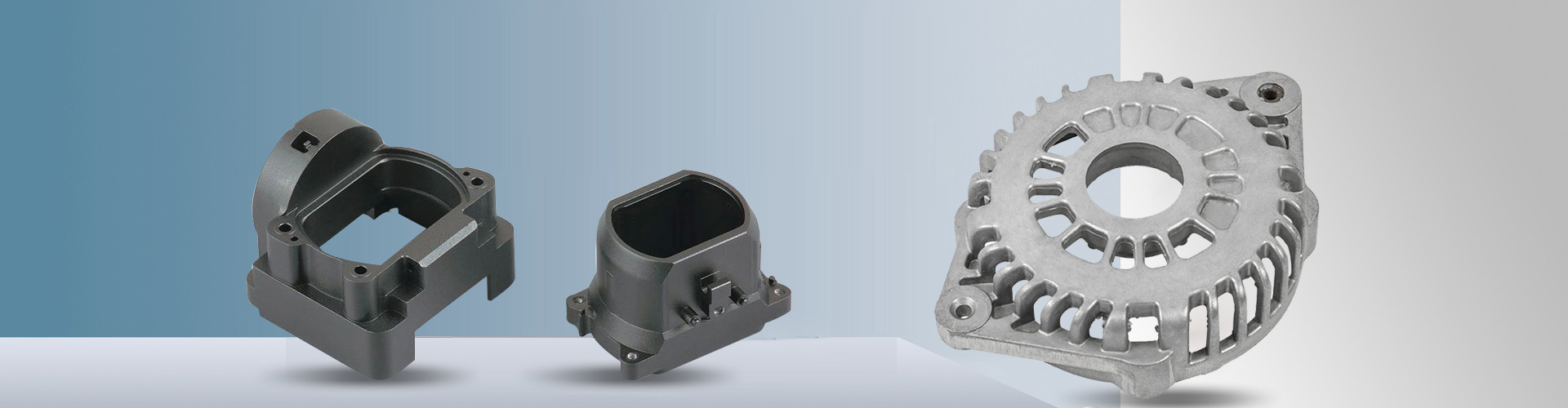

Related Category

Die Casting

Sand Casting

Lost Wax Casting

Hot Forging

Metal Casting

Gravity Casting

Other Casting & Forging

Cold Forging

Vacuum Casting

Mineral Casting

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.