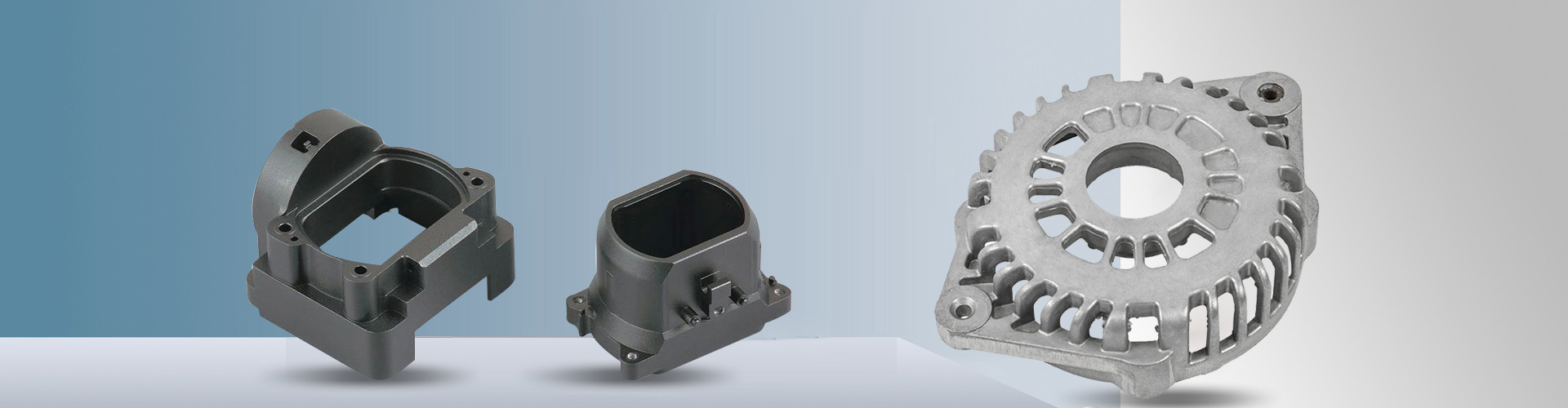

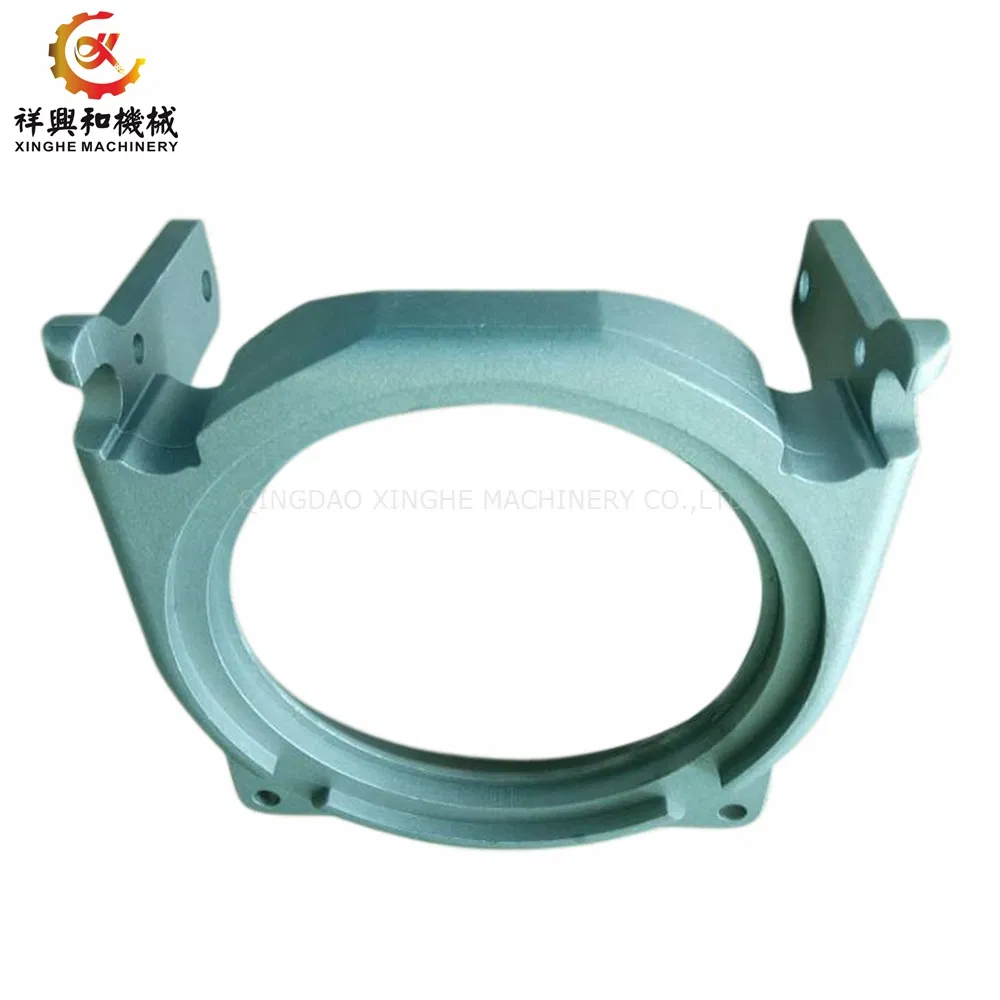

General Products

Application/Service Area |

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

Main blank Process for Casting |

Sand Casting , Resin Sand Casting, Green Sand Casting, Shell Molding, Automatic Molding, Lost Wax Casting, Lost Foam Molding Casting

|

Blanks Tolerance -Casting Tolerance |

CT9-10 for Machine Molding Process,

CT8-9 for Shell Molding and Lost Foam Molding Casting Process

CT10-11 for Manual Molding Sand casting Process |

Applicable Material |

See Table Below (Ductile Iron Casting, Grey Iron Casting)

OR According to customer requirement

|

Casting Blank Size /Dimensions |

2 mm-2000mm / 0.08inch-79inch for casting iron, according to customer requirement |

Casting Blank Weight |

Range from 0.01kg-1000kg for casting iron |

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc.

|

Machining Tolerance |

From 0.005mm-0.01mm-0.1mm |

Machined Surface Quality |

Ra 0.8-Ra3.2, according to customer requirement |

Applicable Heat Treatment |

Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching

|

Applicable Finish Surface Treatment |

Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting.

|

MOQ |

For iron casting : 100pcs

For Machining : 50pcs |

Lead Time |

45days from the receipt date of deposit for iron casting |

Ductile Iron Casting Material Comparison Table:

Cast iron with nomular graphite

DIN EN 1563 |

Germany

DIN 1693 |

France

NF |

Great Britain

BS |

Netherlands

NEN |

Sweden

MNC |

USA

ASTM A536 |

EN-GJS-350-22-LT |

GGG-35.3 |

FGS 370-17 |

370/17 |

GN 38 |

0717-15 |

---- |

EN-GJS-400-18-LT |

GGG-40.3 |

---- |

---- |

---- |

---- |

60-40-18 |

EN-GJS-400-15 |

GGG-40 |

FGS-400-12 |

420/12 |

GN 42 |

0717-02 |

60-40-18 |

EN-GJS-400-10 |

---- |

---- |

420/12 |

---- |

---- |

65-45-12 |

EN-GJS-500-7 |

GGG-50 |

FGS-500-7 |

500/7 |

GN 50 |

0727-02 |

65-45-12/

80-55-06 |

EN-GJS-600-3 |

GGG-60 |

FGS-600-3 |

600/3 |

GN 60 |

0732-03 |

80-55-06 |

EN-GJS-700-2 |

GGG-70 |

FGS-700-2 |

700/2 |

GN 70 |

0737-01 |

100-70-03 |

EN-GJS-800-2 |

GGG-80 |

FGS-800-2 |

800/2 |

|

|

120-90-02 |

EN-GJS-1000-5 (DIN EN 1564) |

GGG-100B/A |

---- |

---- |

---- |

---- |

850-550-10 |

EN-GJS-AX NiSiCr35 5 2 |

GGG-

NiSiCr 35 5 2 |

FGS-

Ni35Si5Cr2 |

S5S |

---- |

---- |

Type D-5S |

Grey Iron Casting Material Comparison Table:

Cast iron with lamellar graphite

DIN EN 1561 |

Germany

DIN 1691 |

France

NF |

Great Britain

BS |

Netherlands

NEN |

Sweden

MNC |

USA

ASTM A48 |

EN-GJL-150 |

GG-15 |

Ft 15 D |

Grade 150 |

GG 15 |

01 15-00 |

20 B / 25 B |

EN-GJL-200 |

GG-20 |

Ft 20 D |

Grade 180/220 |

GG 20 |

01 20-00 |

25 B / 30 B |

EN-GJL-250 |

GG-25 |

Ft 25 D |

Grade 220/260 |

GG 25 |

01 25-00 |

35 B / 40 B |

EN-GJL-300 |

GG 30 |

Ft 30 D |

Grade 300 |

GG 30 |

01 30-00 |

40B / 45 B |

|