CNC Plasma Cutting Machine with Drilling Heads Plasma Cutter

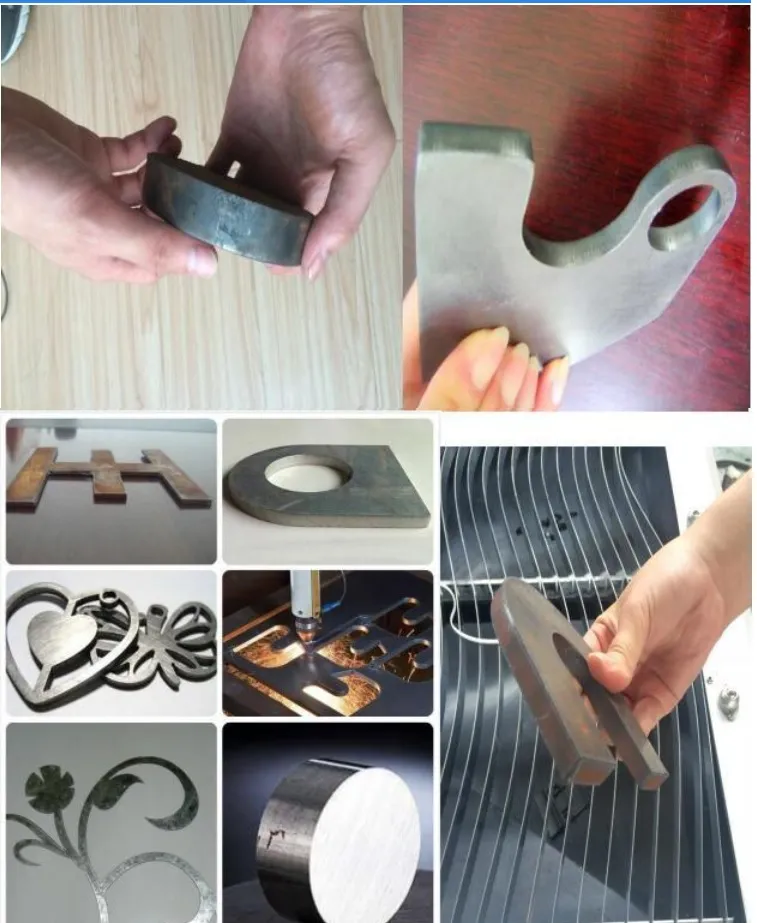

Features of cnc plasma cutter1. Plasma power and cutting gun with high quality, made by famous factories in China.2. Cutting mouth, little and tidy and avoid second trimming.3. Applied for metal sheet, aluminium sleet, stainless sheet, Titanium sheet and so on4. High cutting speed, high precision, a......

Send Inquiry

Product Description

1. Plasma power and cutting gun with high quality, made by famous factories in China.

2. Cutting mouth, little and tidy and avoid second trimming.

3. Applied for metal sheet, aluminium sleet, stainless sheet, Titanium sheet and so on

4. High cutting speed, high precision, and low cost.

5. Plasma power: 20A-60A / 380V, the plasma power can be adjusted.

6. Plasma source adopts advanced integrated module control system, it ensures the high precision and stability.

7. With unique handling with breakpoint and interruption of power supply, it can move forward and backward according to the track.

8. Support Wentai, ARTCAM softwares, Type3 produce standard G code way document, also can change software to read AUTOCAD softwares

9. The control system uses the U-disk exchange processing document, easy to operate.

10. When machine working with water pump and tank provide circulating water cooling.

11. Difference with other factory plasma cutting machine, this machine use screw-ball as drive mode, whic provide high precision for this machine.

Parameter:

| Series | ALLWIN 1530 | ALLWIN 1830 | ALLWIN 1840 |

| Cutting Width(mm) | 1500 | 1800 | 1800 |

| Machine Width(mm) | 2100 | 2400 | 2400 |

| Cutting Length(mm) | 3000 | 3000 | 4000 |

| Machine Length(mm) | 4000 | 4000 | 5000 |

| Control System | USA Micro EDGE pro,Chinese Brand F2300\F2500 or chosen by customer | ||

| Plasma Power Source | USA Hypertherm or chosen by customer | ||

| Cutting Thickness | See also relative plasma power source information | ||

| Drilling Vertical Distance | ≤120 mm | ||

| Drilling Vertical Speed | ≤ 120 mm / S Driven by servo motor (Optional Pneumatic feeding ) | ||

| Drill Turning Speed | 50-1200 n / min Frequency control (Can choose specific speed ) | ||

| Drill Diameter | ≤12 mm | ||

| Drilling Hole Depth | 2 - 30 mm | ||

| Drill Hole Position Accuracy | ±0.15 | ||

| Cutting Platform | Cutting platform with water tank, fit for plasma cutting and drilling .( optional exhaust system) | ||

| Cooling System and Blowing Dust Device | optional | ||

Water-proof plastic film package with foam protection in each corner.

Solid Seaworthy Wood Box Package with Steel Belt.

Save space as much as possible for container loading.

Our Services

# One year warranty for the machine

# Replacing all parts for free during warranty

# If nessessary, provide door to door service to your country

# 12 hours on line service

# Replying your email and offer tecnical service within 24 hours

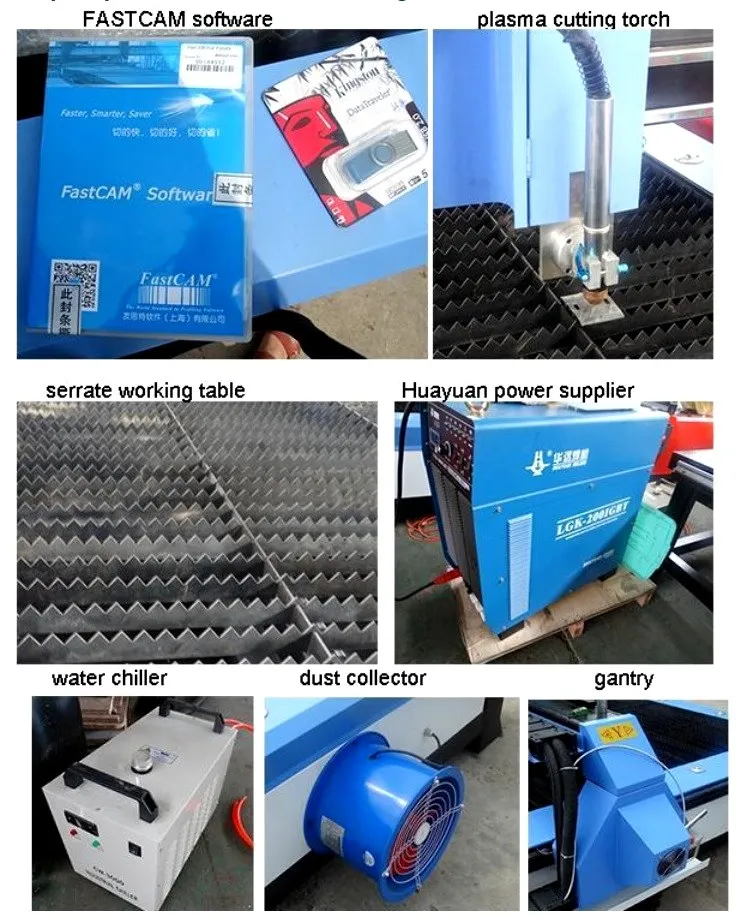

The spare parts of Our Plasma Cutting Machine:

Sample of plamsa machine

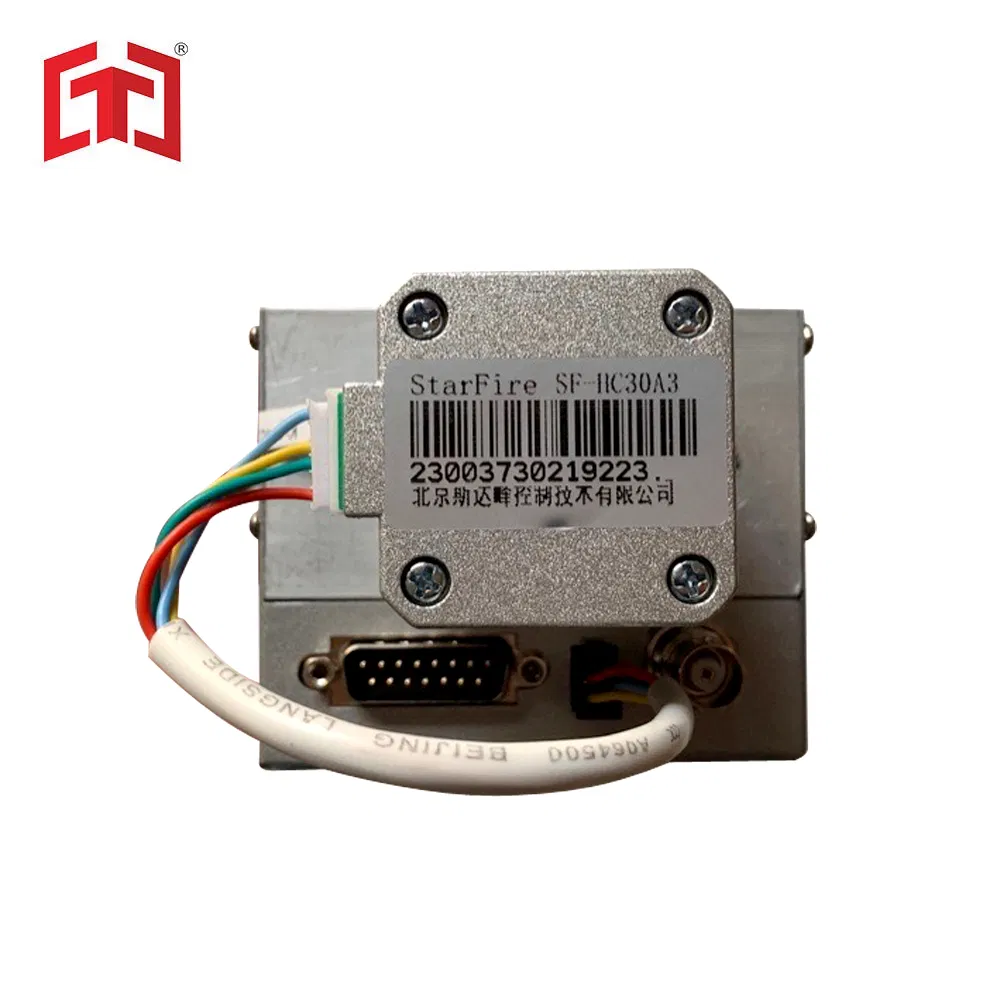

Motor & Drive

1. Adopting China famous brand stepper motor and driver, stable performance, high response speed, good anti jamming capability.

2. All the machine's signal wire is high flexible shielded wire, heat resistant, low temperature resistant, bend resistant.

3. Control signal uses 24V voltage, with famous brand switch power supply.

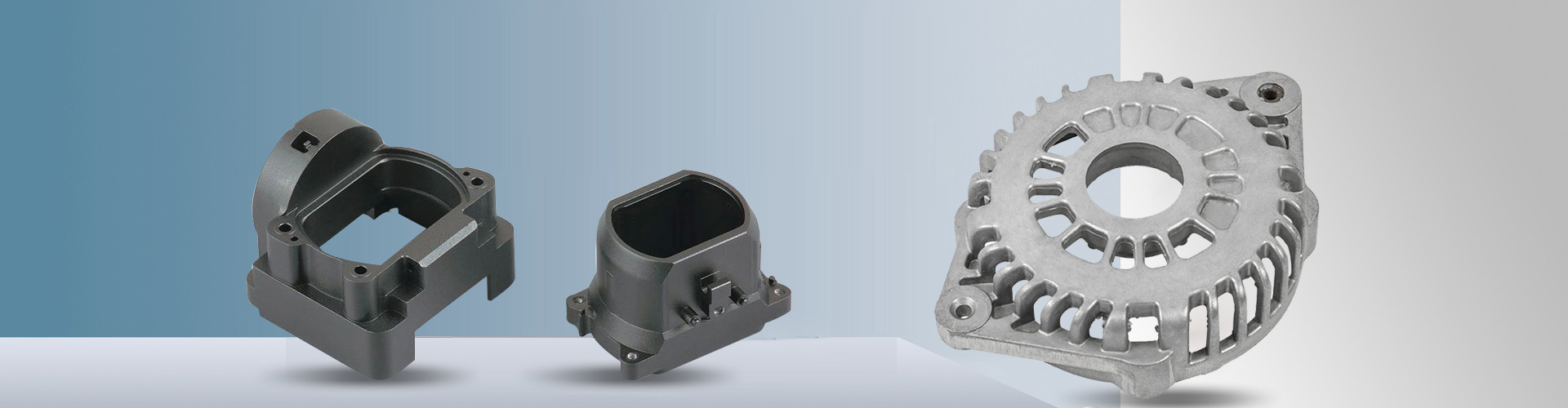

Machine bed part

1. The whole machine bed adopts welded steel structure and then precision-machined, whole tempering, fully eliminate welding stress, stable and reliable performance. Gantry and end beam adopts cast aluminum and then precision-machined, moving performance is good.

2. Dual driving for Y-axis, XY-axis adopts high precision linear square guide rail, Hiwin, Taiwan, good oriented, high precision. Transmission is high precision helical rack and pinion, customized by the specialized manufacturer, surface carburizing quench, stable moving and high precision.

3. Dust proof system on the gantry, effectively prevent the dust going into guide rail and rack during cutting, extend the machine life time, also make machine more beauty,

4. Special fume dust extractor,and down draft cutting table and slag storage device, create a good working environment.