Plastic Mould for Robot

Injection Plastic Toy Mould for RobotItemsInjection plastic mold for RobotParts materialsPC, ABS, PP, PE(also other material like PS, PMMA, PC+ABS, PP+TD20%, PU, PA6, PVC,Silicone)Mold base steelNAK80, S136, SKD61,45, S55C, P20, 1730, 2738, 718h, H13, BPMHH, 2343ESRCore and cavity steelNAK80, S136,......

Send Inquiry

Product Description

| Items | Injection plastic mold for Robot |

| Parts materials | PC, ABS, PP, PE (also other material like PS, PMMA, PC+ABS, PP+TD20%, PU, PA6, PVC,Silicone) |

| Mold base steel | NAK80, S136, SKD61,45, S55C, P20, 1730, 2738, 718h, H13, BPMHH, 2343ESR |

| Core and cavity steel | NAK80, S136, SKD61, P20,1730hh, 2738hh, 718h, H13, BPMHH, 2343hh |

| Injection system | Edge gate, slid gate, sub gate, direct gate, pin point gate, valve gate |

| Mould standard | DME, LKM, HASCO |

| Cavity numbers | Single or multi |

| Runner | Hot or cold |

| Injection machine | 100-1500T |

| Cycle time | 10-120 seconds |

| Mold of steel suppliers | Finkl, Assab, Daidao, LKM, Buderus |

| Hot runners suppliers | Synventive, Yudo, Incoe, Hasco, DME, Moldmaster, HRS, Delachaux |

| Mould life | 300,000 - 1,000,000 shots |

| Tooling lead-time | 15-40 days depends on qty and complexity of mold |

| Design software | Pro/E, UG, Catia, Solidwork, Moldflow, AutoCad |

| Mould life | 300,000-1,000,000 shots |

| Shipping packing | Wooden case or according to customer's requirements |

| Certificate | ISO9001:2015 |

If you have demand on developing Robot or other projects, we will be happy to receive your sample or 2D/3D drawing, then we can offer plastic mould design, rapid prototype, mold manufacture, parts injection, printing, assembling one stop service for you.

Our advantage:

Good price

High Quality Products

Professional Service

We have exported to more than 30 countries and we get high evaluation from our customers. If you have any demand, pls do not hesitate to

Contact us

Julia Zhu

Green Vitality Industry Co.,Ltd

Mob: 0086- 18682032380

Tel: 0086-0755-2682 5352 ext 806

Fax: 0086-0755-2668 9654

Web: http://greenvitality.en.made-in-china.com

We make more than Molds!

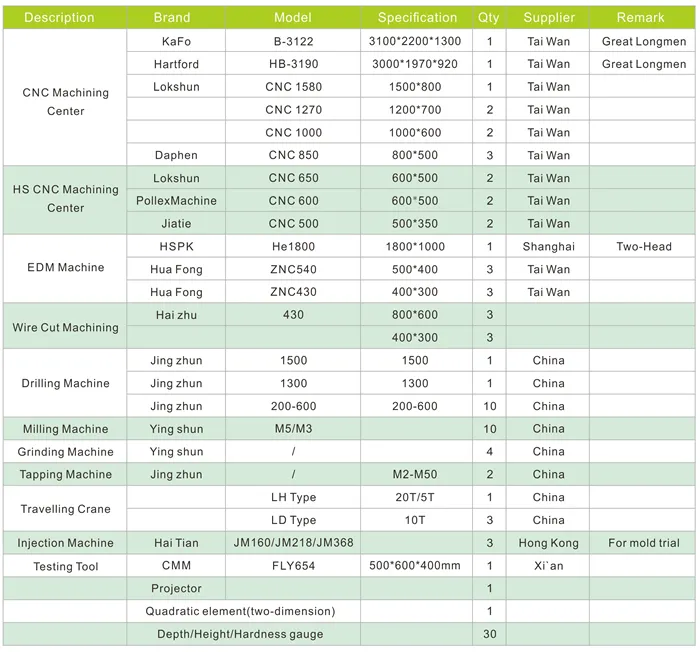

Mold Manufacture Equipment

Green Vitality Industry CO., Limited was founded in 1997,as starting fron CNC processing in a small tooling building in Chang'an town, with 22 years experience in custom tooling and injection molding, nowadays we have become one of the global famous mold makers in manufacturing large plastic injection molds.

With the modern business management system and ISO9001:2008 Quality System guideline, the sophisticated production techniques, the advanced manufacturing equipment, and our qualified and dedicated team, we are full of capabilities and have great confidence in offering you professional one-stop solution of mold designing, mold making, injection molding and beyond-value service.

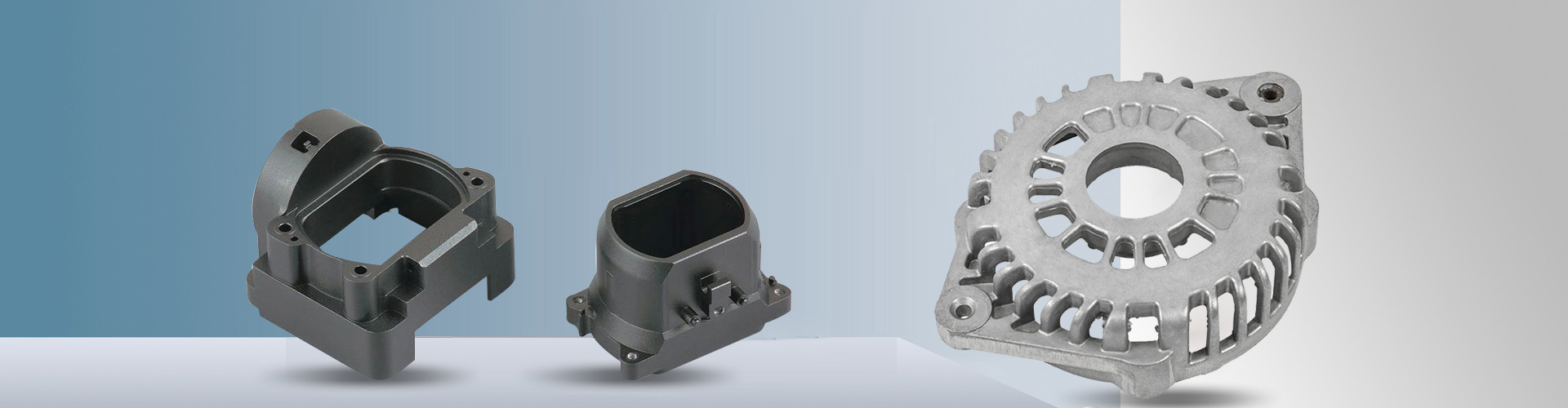

We serve a broad range of customers in the field of Auto Parts, Aero parts, Household Appliance, Industrial and Beauty. Green Vitality make over 400 molds per year, mainly of the molds and plastic parts are exported to America, Germany, France, Turkey, Italy and other countries worldwide.

We have established long-term cooperation with our clients and are continually improve top quality molds and plastic parts to our clients, establishing close strategic partnership to keep customer's satisfaction and success, growing up together with customers.

Factory Profile

6000 square meters mold making workshop, 8,000 square meters injection workshop.

With 160 employees, including 20 engineers, mold maker 65 people, injection molding 60 people.

Factory Capability:

40 molds per month, 500sets per year.

Max. mold size 3200x2200mm, Max. mold weight 25 tons

Service Scope:

Expert in Auto Parts, Aero parts and Household Appliance large plastic molds

Plastic parts injection

Prototype parts

Market Advantage:

Top quality mold and plastic parts

Reliable service

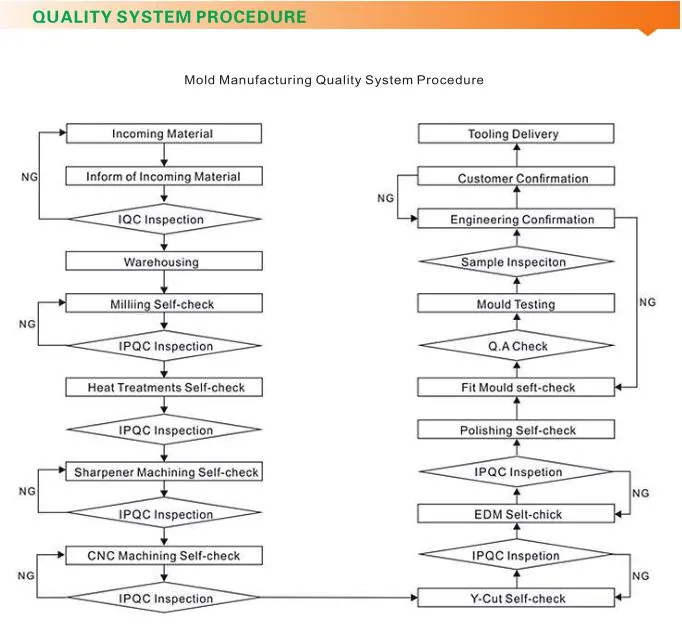

Quality managemant