Home > Products > Mould > Rubber Mould > Custom Silicone Injection Molding Transfer|Compression Moulding Rubber Mold

Custom Silicone Injection Molding Transfer|Compression Moulding Rubber Mold

Silicone Injection Molding Transfer|Compression Moulding Rubber MoldRubber Mold can be machined by various processing ways into a certain shape and then used for molding different shapes of silicone rubber parts, such as O Ring, Gasket & Seals, Bushing, Sleeve, Grommet, etc. Basic Properties1Ste......

Send Inquiry

Product Description

Silicone Injection Molding Transfer|Compression Moulding Rubber Mold

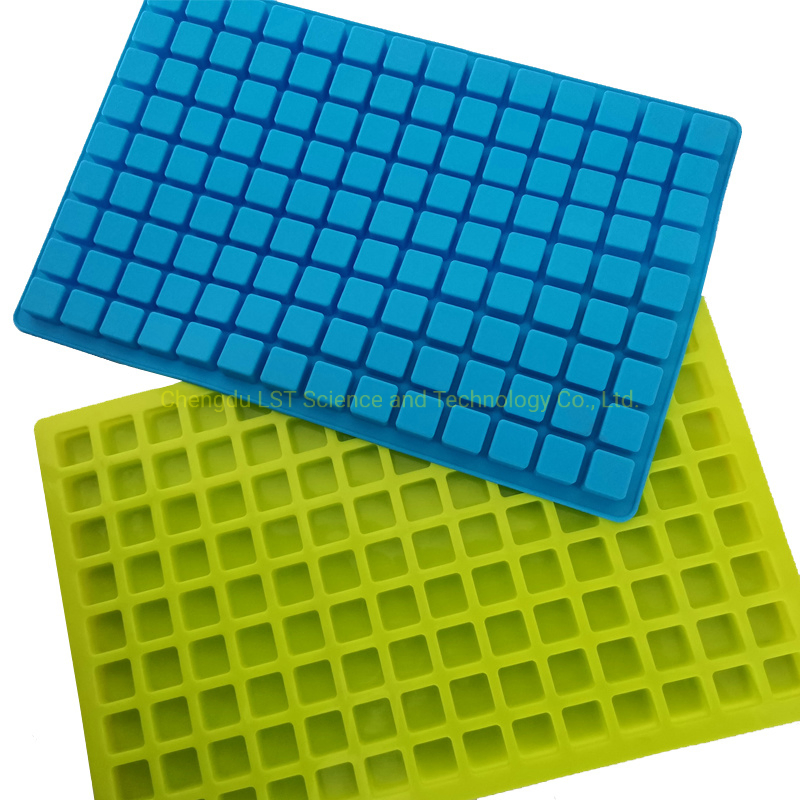

Rubber Mold can be machined by various processing ways into a certain shape and then used for molding different shapes of silicone rubber parts, such as O Ring, Gasket & Seals, Bushing, Sleeve, Grommet, etc.

Basic Properties

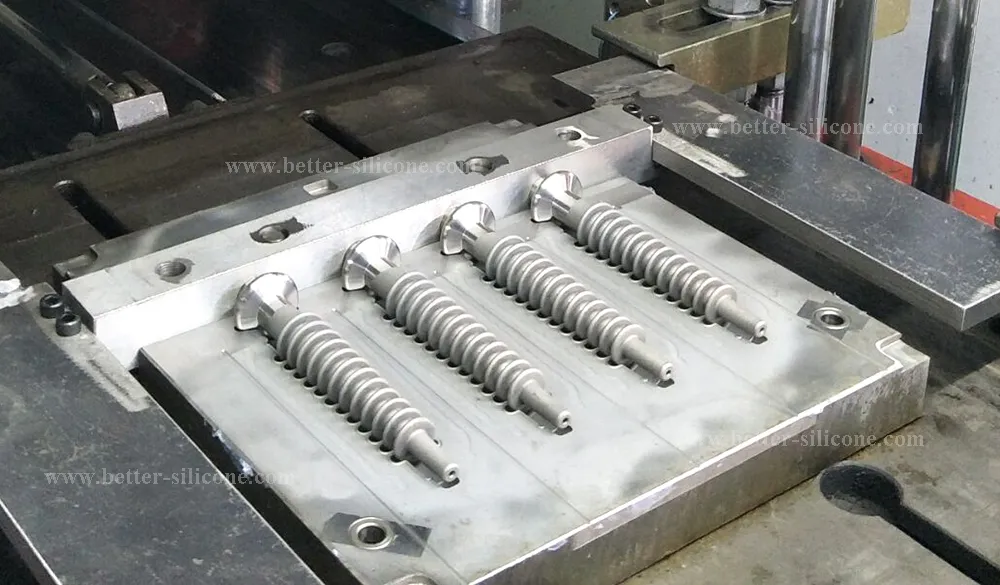

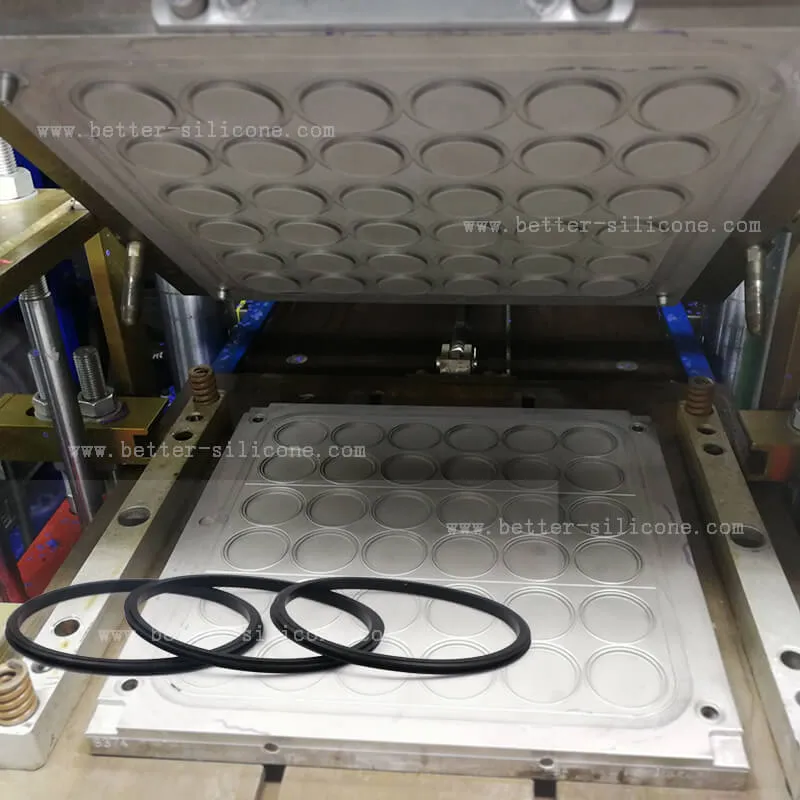

Rubber Compression Mold Structure:

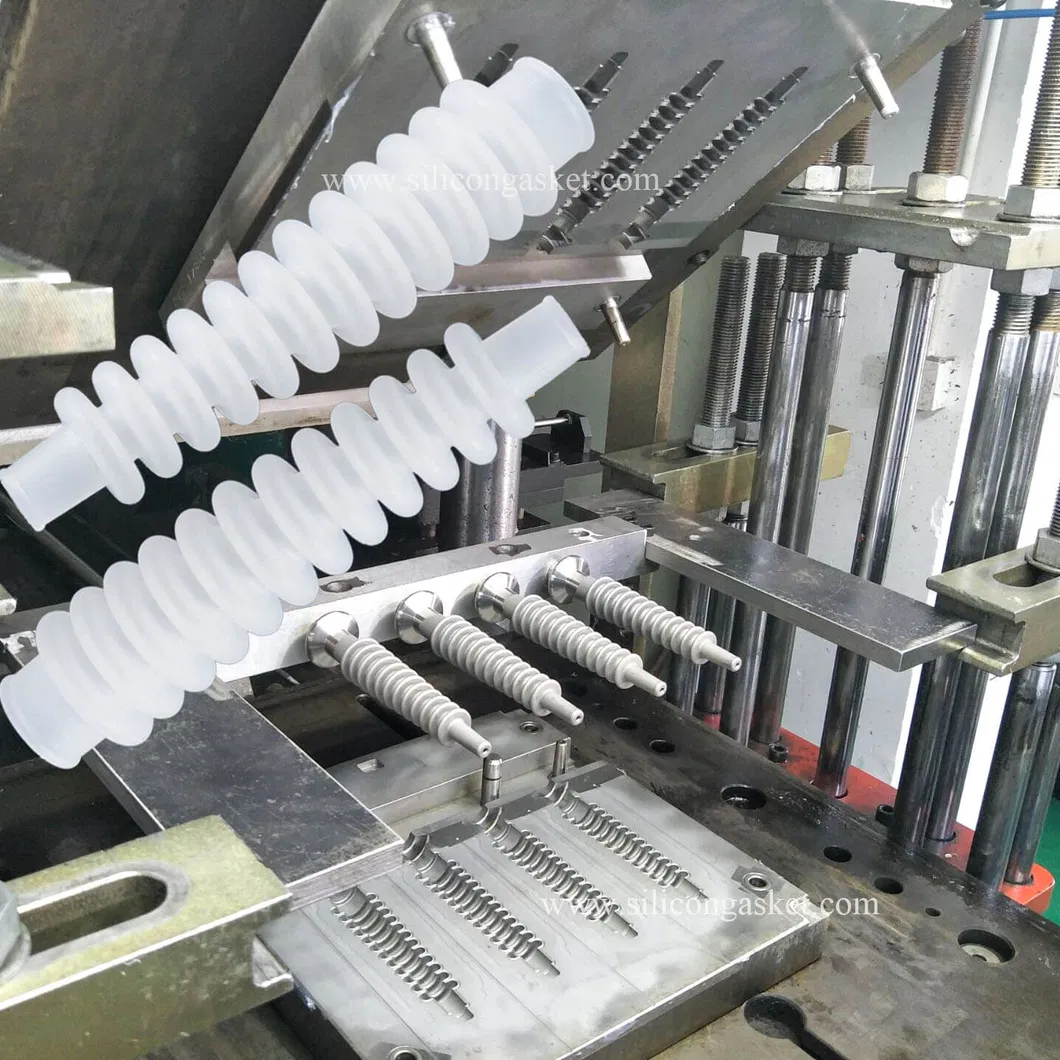

Silicone compression mould with moving core

(ejecting mechanism: help to take out product from mold and avoid product from pulling injury/damage)

Rubber compression mold with mold keel

(Mainly for some product with hollow-design structure)

Silicone rubber compression mold with middle plate

(Mainly for some product with undercut-design structure)

Silicone Compression Mold Types:

Two-Plate Compression Mold

Three-Plate Compression Mold

Rubber Transfer Injection Mold

Quickly Quotation Demands For Rubber Mould

1.2D/3D designs Drawings, Samples, or other basic information

2.Materials Demands:Rubber ID(Rubber, Solid Silicone/LSR )

3.Mold Cover/Base Steel Demands(or mold shot life).

4. Surface Demands.

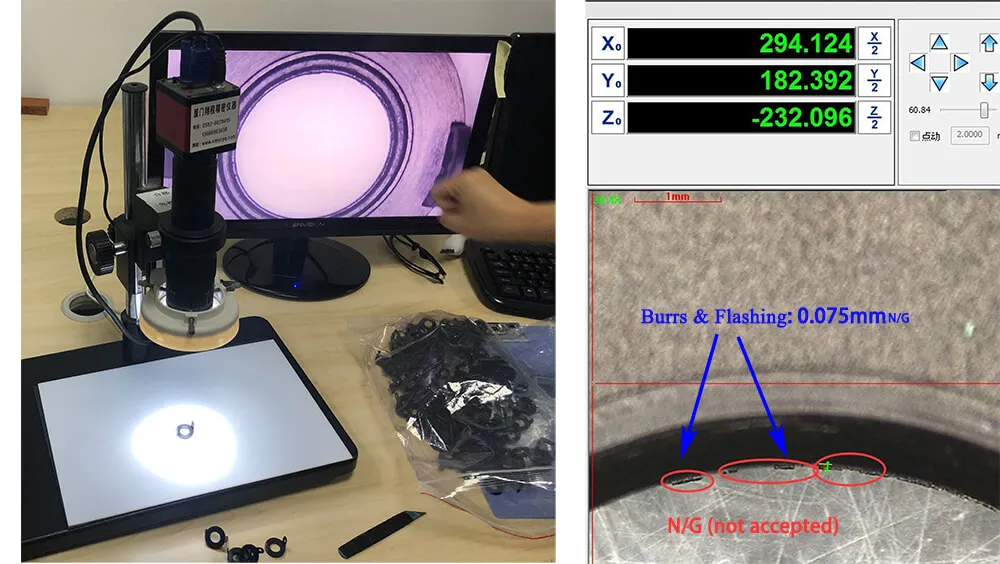

5. Sizes Tolerance Demands: +/-0.005mm - +/-0.3mm

Our Factory

Xiamen Better Silicone Rubber Co., LTD, established in the year of 2018, is the production base of Xiamen Better Silicone Import and Export Co., LTD (established in 2015), who is specialized in manufacturing precision silicone rubber parts, LSR (liquid silicone rubber) parts and plastic components. Better Silicone aims at providing the comprehensive one-stop solutions and service throughout the entire production process, from product design analysis, mold design and mold making, sample & prototype, mass production stage and then ready-to-use products (finished product). Our Products can be widely used in Electronic Field, Medical Field, Auto parts & machinery parts field, etc.

Rubber Mold can be machined by various processing ways into a certain shape and then used for molding different shapes of silicone rubber parts, such as O Ring, Gasket & Seals, Bushing, Sleeve, Grommet, etc.

Basic Properties

| 1 | Steel material | 45#,50#,718,8407,S136,NAK80,P20,KD-61,NIMAX,2343,DIN-1, 2738,S130,H13,2344,738H,ect |

| 2 | Steel hardness | 20-60HRC |

| 3 | Treatment | Pre-Harden, Nitriding, Heat treatment, Quenching, |

| 4 | Cavity Qty | Single-cavity / Multi-cavity |

| 5 | Plastic material | PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE etc |

| 6 | Mould Life | 50K - 100K shots |

| 7 | Design Software | UG, CAD, 3D MAX ,PRO-E, Solid Works etc, |

| 8 | Process | CNC, high speed carve, EDM, wiring-cutting, drill, polish etc |

| 9 | Quality | ISO9001:2000 Certificate |

| 10 | Lead Time | 10-30 workdays depends on the different products |

| 11 | Package | Wooden Case Package or according to customer requirement |

Rubber Compression Mold Structure:

Silicone compression mould with moving core

(ejecting mechanism: help to take out product from mold and avoid product from pulling injury/damage)

Rubber compression mold with mold keel

(Mainly for some product with hollow-design structure)

Silicone rubber compression mold with middle plate

(Mainly for some product with undercut-design structure)

Silicone Compression Mold Types:

Two-Plate Compression Mold

Three-Plate Compression Mold

Rubber Transfer Injection Mold

Quickly Quotation Demands For Rubber Mould

1.2D/3D designs Drawings, Samples, or other basic information

2.Materials Demands:Rubber ID(Rubber, Solid Silicone/LSR )

3.Mold Cover/Base Steel Demands(or mold shot life).

4. Surface Demands.

5. Sizes Tolerance Demands: +/-0.005mm - +/-0.3mm

Our Factory

Xiamen Better Silicone Rubber Co., LTD, established in the year of 2018, is the production base of Xiamen Better Silicone Import and Export Co., LTD (established in 2015), who is specialized in manufacturing precision silicone rubber parts, LSR (liquid silicone rubber) parts and plastic components. Better Silicone aims at providing the comprehensive one-stop solutions and service throughout the entire production process, from product design analysis, mold design and mold making, sample & prototype, mass production stage and then ready-to-use products (finished product). Our Products can be widely used in Electronic Field, Medical Field, Auto parts & machinery parts field, etc.

Related Category

Plastic Mould

Stamping Die

Mould Parts

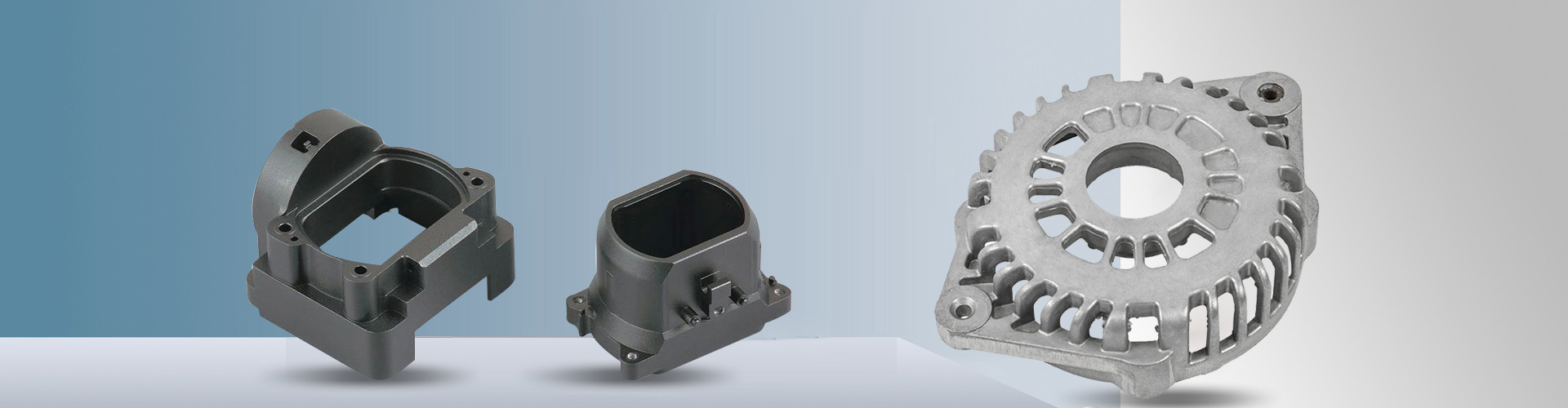

Die-Casting Mould

Rubber Mould

Metal Casting Mould

Forging Mould

Other Moulds

Extrusion Die

Preform Mould

Drawing Die

Blowing Mould

Compression Mould

Economic Mould

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.