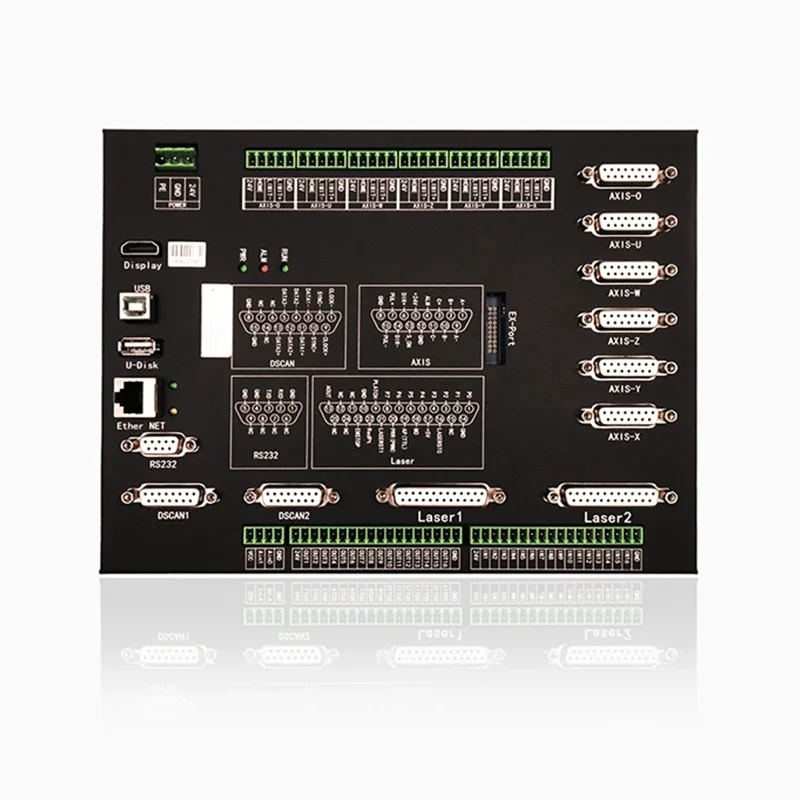

Galvanometer Dual Flight Laser Control Board PID control mode

2025-06-24

The PID (Proportional-Integral-Derivative) control mode offers several key advantages when applied to a Galvanometer Dual Flight Laser Control Board. These advantages improve precision, stability, and responsiveness, which are critical in high-speed laser applications. Here's a breakdown of the benefits:

1. High Precision Positioning

Proportional control (P) ensures immediate correction based on the current error.

This allows the galvanometer to maintain highly accurate laser positioning even at high speeds.

2. Reduced Overshoot and Oscillation

The derivative term (D) predicts system behavior and dampens response, preventing overshooting and minimizing vibrations.

This is crucial in laser engraving or cutting to avoid distortion or blurred edges.

3. Stable Long-Term Performance

The integral component (I) eliminates residual steady-state error by adjusting control output over time.

Ensures that the galvanometer eventually reaches and stays at the desired angle with minimal drift.

4. Fast Dynamic Response

PID controllers allow for real-time adjustments, which is essential in dual-flight mode where X and Y galvanometers must synchronize rapidly.

Enhances the overall throughput of laser systems with minimal lag or delay.

5. Adaptive to Load Variations

Laser systems may face varying loads or resistance due to different scanning patterns.

PID control dynamically adapts to these variations, maintaining consistent motion quality.

6. Improved Laser Marking Quality

Better control over scanning path results in cleaner lines, sharper edges, and higher-quality output.

Especially beneficial in high-precision fields like electronics, micro-engraving, or medical device marking.

In summary, using PID control mode in a galvanometer dual flight laser control board enhances accuracy, response time, and system stability, making it ideal for high-speed, high-precision laser processing environments.

As a professional manufacturer and supplier, we provide high-quality products. If you are interested in our products or have any questions, please feel free to contact us.