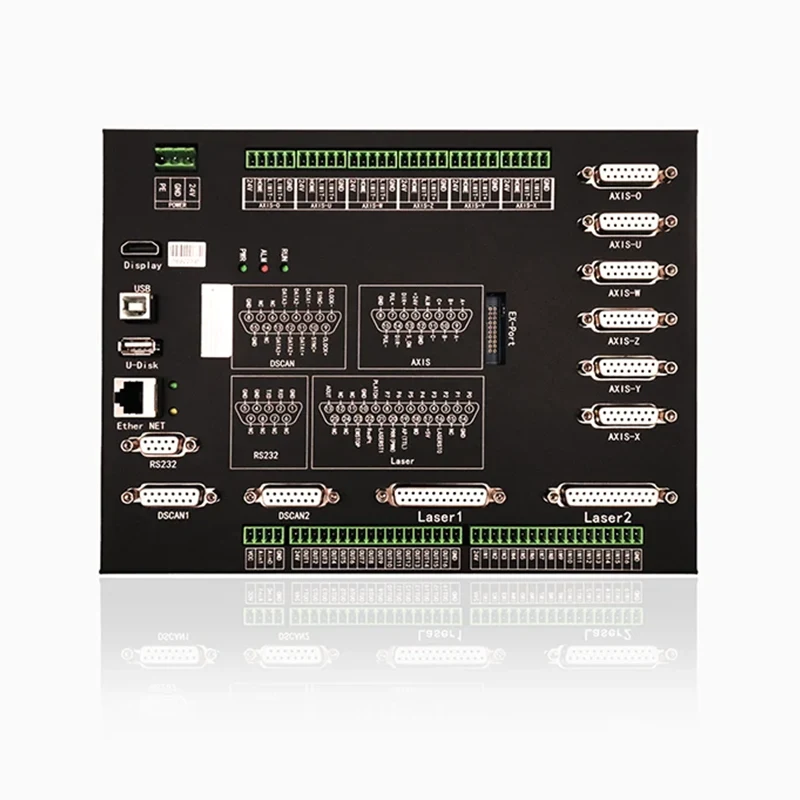

Galvanometer Dual Flight Laser Control Board

2025-06-24

In the field of precision laser systems, the Galvanometer Dual Flight Laser Control Board plays a pivotal role in enhancing the accuracy, efficiency, and flexibility of laser marking, engraving, and cutting applications. This advanced piece of hardware is designed to manage and coordinate the operation of galvanometer scanners and laser sources in dual-flight configurations, making it indispensable in high-speed, high-precision industrial environments. The following essay outlines the key features that make the Galvanometer Dual Flight Laser Control Board a crucial component in modern laser systems.

1. Dual-Channel Synchronization

One of the standout features of the Galvanometer Dual Flight Laser Control Board is its ability to simultaneously manage two independent galvanometer scan heads. This dual-channel operation enables synchronized laser output on separate working areas, significantly increasing throughput in mass production settings. With precise timing control and seamless coordination, manufacturers can optimize material usage and reduce processing time.

2. High-Speed Data Processing

Equipped with a powerful processor and high-bandwidth data transmission capabilities, the control board supports rapid command execution and real-time feedback. This feature ensures that complex patterns or text can be marked or engraved at high speeds without compromising on precision. It also supports high-resolution vector and bitmap files, which are essential in demanding industrial and artistic applications.

3. Advanced Motion Control Algorithms

The control board incorporates sophisticated motion control algorithms to enhance the accuracy and stability of the galvanometer system. These algorithms help reduce vibrations and distortions during high-speed operations, ensuring clean and crisp output. Compensation mechanisms for speed-dependent positioning errors further improve the reliability of the system.

4. Multi-Laser Compatibility

Another important feature is the board’s ability to interface with various types of laser sources, including fiber lasers, CO₂ lasers, and UV lasers. This versatility allows it to be integrated into diverse manufacturing processes such as metal engraving, plastic marking, and PCB etching, expanding its application scope across multiple industries.

5. Real-Time Monitoring and Diagnostics

The control board typically includes real-time monitoring features that provide feedback on system status, laser output, temperature, and scanner health. Diagnostic tools help identify potential issues early, enabling preventive maintenance and reducing unexpected downtime.

6. User-Friendly Software Interface

A comprehensive and intuitive software interface accompanies the control board, allowing users to configure scanning parameters, import design files, and adjust laser settings with ease. This software often supports industry-standard design formats and includes simulation functions to preview operations before execution.

7. Modular Design and Expandability

Most dual flight control boards are designed with modular architecture, which allows for future upgrades and system expansion. Additional channels, sensors, or I/O ports can be integrated without the need to redesign the entire control system, offering flexibility for evolving production needs.

Conclusion

The Galvanometer Dual Flight Laser Control Board is a cornerstone of modern laser processing systems, enabling higher productivity, improved precision, and greater versatility. Its dual-channel synchronization, high-speed processing, and multi-laser compatibility position it as a high-performance solution for industries ranging from automotive and aerospace to electronics and art. As laser technologies continue to advance, the capabilities of control boards like this will remain crucial in pushing the boundaries of what is possible in laser-based manufacturing.

As a professional manufacturer and supplier, we provide high-quality products. If you are interested in our products or have any questions, please feel free to contact us.