How do Tire Building Machine provide advanced manufacturing solutions for tire production?

2025-08-06

Precision Engineering for High-Quality Tire Assembly

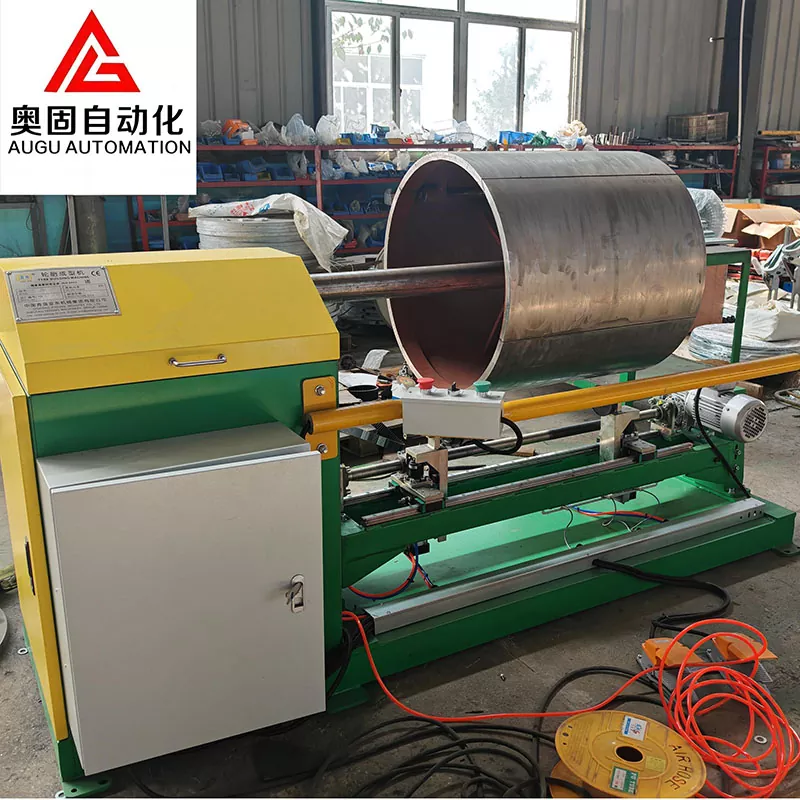

Our Tire Building Machines (TBM) are engineered to deliver superior performance in tire manufacturing, ensuring precision, efficiency, and consistency in every production cycle. Designed for both radial and bias-ply tires, these machines from Augu streamline the assembly process while maintaining the highest quality standards for passenger, truck, OTR, and specialty tires.

Key Features & Benefits

✔ High-Speed Automation – Reduces cycle time with robotic integration

✔ Multi-Stage Building – Handles carcass, belt, and tread assembly in one system

✔ Precision Control – Servo-driven components for accurate ply/tread placement

✔ Modular Design – Adaptable for different tire sizes and constructions

✔ Smart Monitoring – IoT-enabled diagnostics for predictive maintenance

Technical Specifications

Machine Configurations & Capabilities

| Model Series | Tire Type | Max Diameter | Production Speed | Automation Level |

|---|---|---|---|---|

| TBM-2000 | Passenger (Radial) | 24" | 120 tires/hour | Fully Automated |

| TBM-3000 | Truck/Bus (Radial) | 42" | 80 tires/hour | Semi-Automated |

| TBM-5000 | OTR (Mining/Agri) | 63" | 30 tires/hour | Robotic Integration |

| TBM-Flex | Specialty (Bias/Run-Flat) | Custom | 50-100 tires/hour | Hybrid (Manual/Auto) |

Core Components & Performance

| Component | Specification | Technology |

|---|---|---|

| Drum Assembly | Segmented, servo-adjusted | Zero-Stitch Technology |

| Ply Application | Laser-guided alignment | Auto-Tension Control |

| Bead Setting | Robotic placement | Force-Feedback System |

| Tread Stitching | Multi-roller system | Uniform Pressure Control |

| Control System | PLC + HMI Interface | Industry 4.0 IoT Connectivity |

Applications & Tire Types Supported

✔ Passenger Tires – High-speed radial assembly

✔ Truck & Bus Tires – Heavy-duty carcass construction

✔ OTR & Mining Tires – Reinforced ply handling

✔ Military/Aviation Tires – Specialty compound compatibility

✔ Green Tire Building – Eco-friendly, low-waste production

Tire Building Machine FAQ

Q: What is the difference between a 1st-stage and 2nd-stage TBM?

A: 1st-stage machines assemble the tire carcass (inner liner, plies, beads), while 2nd-stage machines add belts, treads, and final stitching. Our TBM-Integrated Series combines both stages for seamless production.

Q: Can your machines handle run-flat or self-sealing tire construction?

A: Yes! The TBM-Flex Pro model supports:

-

Run-flat sidewall reinforcement

-

Self-sealing gel layer integration

-

Multi-layer ply application for specialty tires

Q: How does IoT integration improve tire building efficiency?

A: Our smart monitoring system provides:

✔ Real-time tension/alignment feedback

✔ Predictive maintenance alerts

✔ Production analytics for quality control

✔ Remote troubleshooting via cloud connectivity

Why Choose Our Tire Building Machines?

✅ Proven Reliability – Used by top-tier tire manufacturers globally

✅ Energy Efficient – Reduced power consumption vs. legacy systems

✅ Quick Changeover – Adjustable drums for multiple tire sizes

✅ 24/7 Support – On-call engineers + spare parts availability

✅ Custom Solutions – Tailored for niche tire production needs

Upgrade Your Tire Production Line Today!

Maximize output and minimize defects with our next-gen Tire Building Machines. Contact our engineering team for:

-

Free feasibility analysis for your production needs

-

Live demo at our facility or yours

-

Financing/Lease options for capital equipment

Request a quote now and discover how our machines can optimize your tire manufacturing process! 🚀