How Does the HD Series Bevel Geared Unit Enhance Industrial Efficiency?

2025-08-26

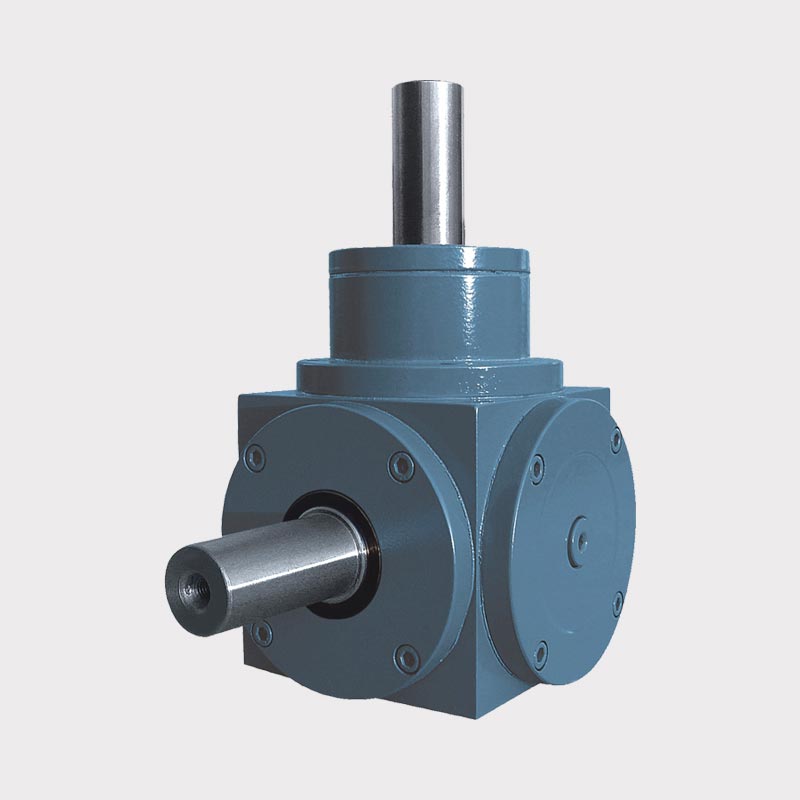

In modern industrial environments, operational efficiency, equipment durability, and energy optimization are critical factors that directly influence production performance. Among the most essential components in high-demand machinery, the HD Series Bevel Geared Unit has emerged as a reliable solution for heavy-duty power transmission. Engineered with advanced bevel gear technology, this series is widely adopted across sectors like material handling, mining, steel processing, cement manufacturing, and automated production lines.

This article explores how the HD Series Bevel Geared Unit works, why it is preferred over conventional gear units, its detailed specifications, practical applications, and frequently asked questions. By the end, you’ll understand why industries across the globe rely on this technology for stable, efficient, and high-performance operations.

What Is the HD Series Bevel Geared Unit?

The HD Series Bevel Geared Unit is a robust and precision-engineered gearbox designed for heavy-duty applications. It combines bevel and helical gear technology, allowing smooth torque transmission at various speed ratios while maintaining energy efficiency and minimal noise. This series stands out because of its compact structure, high load-bearing capacity, and long operational lifespan.

Unlike traditional gearboxes, the HD Series uses high-strength alloy steel gears that are case-hardened and ground for enhanced durability. Its modular design enables multiple mounting options, making it adaptable for diverse industrial setups. Whether horizontal, vertical, or inclined installations are required, this series delivers consistent performance.

Key Advantages:

-

High Transmission Efficiency: Advanced bevel-helical gear combination reduces energy loss.

-

Durable Design: Premium materials and heat treatment ensure long service life.

-

Versatility: Compatible with multiple machinery types and mounting configurations.

-

Noise Reduction: Optimized tooth geometry minimizes operational noise.

-

Low Maintenance: Fewer wear components lower upkeep costs.

Technical Specifications of the HD Series Bevel Geared Unit

To meet the demands of modern industry, the HD Series incorporates cutting-edge manufacturing techniques and strict quality controls. Below is an overview of its technical specifications to demonstrate why it’s a preferred choice in power transmission solutions.

| Parameter | HD Series Specification |

|---|---|

| Gear Type | Bevel + Helical Combination |

| Torque Range | Up to 500,000 Nm |

| Power Range | 0.25 kW – 5,000 kW |

| Speed Ratio | 5:1 to 400:1 |

| Input Types | Solid shaft, hollow shaft, or flange-mounted motor |

| Output Shaft Types | Solid, hollow, or spline connections |

| Mounting Options | Horizontal, vertical, inclined |

| Material | High-strength alloy steel |

| Surface Treatment | Case-hardened & precision-ground gears |

| Lubrication System | Splash or forced lubrication |

| Noise Level | ≤ 65 dB under normal load |

| Temperature Range | -40°C to +80°C |

| Protection Grade | IP55 / IP65 depending on application |

These specifications highlight the adaptability of the HD Series across a wide spectrum of industrial applications, from light-duty operations to extremely demanding environments.

How the HD Series Bevel Geared Unit Improves Industrial Performance

Industries today demand efficiency, stability, and reliability, and the HD Series has been designed with these priorities in mind. Here's how it contributes to improved productivity and operational stability:

Optimized Torque Transmission

By combining bevel gears for directional torque transfer and helical gears for smoother load handling, the HD Series achieves high torque outputs without compromising precision. This makes it ideal for applications such as conveyor belts, crushers, mixers, and other machinery where consistent torque is critical.

Energy Efficiency and Cost Reduction

The advanced gear design minimizes frictional losses, translating to less energy consumption. Over the long term, businesses benefit from lower operational costs and improved ROI.

High Load Capacity and Durability

Industrial environments often involve extreme loads, shocks, and vibrations. With hardened gears, reinforced housings, and optimized tooth profiles, the HD Series can withstand harsh conditions while maintaining reliability.

Versatility Across Applications

The modular design and multiple shaft options make the HD Series suitable for diverse applications, including:

-

Mining and Quarrying: Handling high torque for crushers and screening equipment.

-

Steel Production: Driving rolling mills and material transfer systems.

-

Cement Manufacturing: Supporting heavy-duty kilns and grinding mills.

-

Automated Systems: Ensuring precision and stability in robotics and conveyor systems.

Q1: What makes the HD Series better than standard gear units?

Answer: Unlike conventional gearboxes, the HD Series combines bevel and helical gears to achieve high torque transmission efficiency and low energy loss. Its modular construction allows flexible mounting and compatibility with various industrial setups. Additionally, its advanced materials and optimized lubrication systems ensure longer service life and lower maintenance costs.

Q2: How do I choose the right HD Series Bevel Geared Unit for my application?

Answer: Selecting the correct model depends on factors such as required torque, speed ratio, installation space, and operational environment. First, determine your machinery's power needs and load specifications. Then, consult the product's torque and speed charts to identify a compatible unit. For specialized or high-demand applications, it's advisable to work directly with a manufacturer like Donghai for customized solutions.

In industries where efficiency, reliability, and durability determine profitability, the HD Series Bevel Geared Unit stands out as a powerful solution. With its advanced engineering, wide torque range, and adaptability across diverse applications, it is the preferred choice for global manufacturers seeking optimized performance.

At Donghai, we combine years of manufacturing expertise with cutting-edge technology to deliver high-quality HD Series Bevel Geared Units tailored to your operational needs. Whether you need standard models or custom-engineered solutions, we ensure superior durability, exceptional energy efficiency, and seamless integration into your systems.

If you are ready to upgrade your industrial performance with the HD Series Bevel Geared Unit, contact us today to discuss your requirements and explore customized solutions designed to keep your operations running at peak efficiency.