How Much do CNC Precision Metal Parts Cost?

2025-10-31

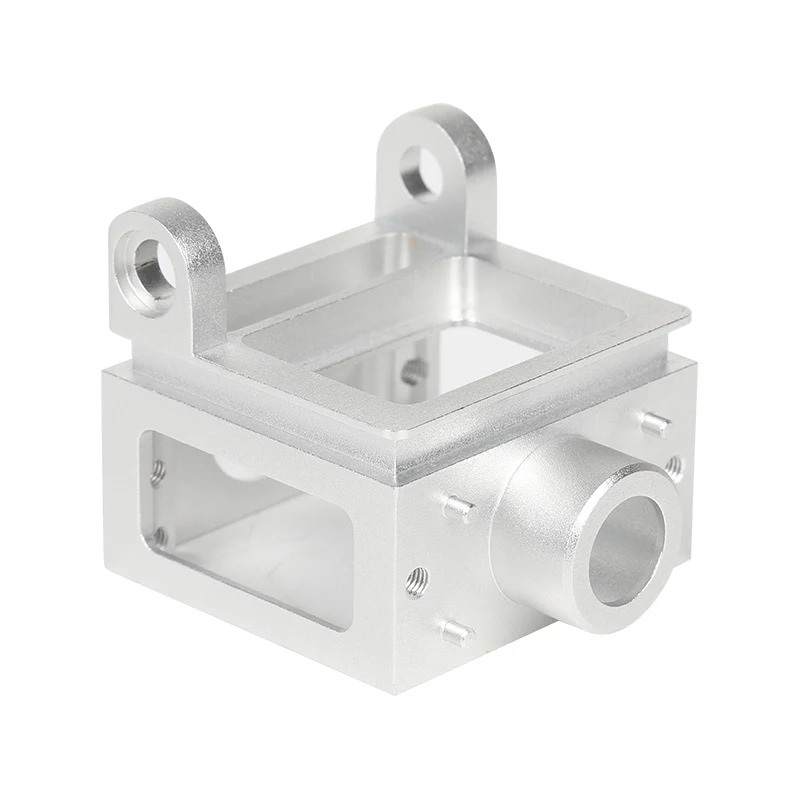

CNC precision metal parts play an essential role in modern manufacturing, from automotive and aerospace to medical devices and industrial machinery. However, one of the most common questions customers ask is, “How much do CNC precision metal parts cost?” The answer depends on various factors, including materials, design complexity, machining tolerance, and order quantity. At Shenzhen Zhihexing Electromechanical Co., LTD., our factory provides professional CNC Machining of Non-Standard Fasteners with accurate cost control and high-quality standards.

Factors Affecting the Cost of CNC Precision Metal Parts

The cost of CNC precision metal parts varies depending on multiple production and design factors. Below are the main elements that influence pricing in our factory’s CNC machining process:

2. Machining Time: Complex geometries require more programming and cutting time, leading to higher costs.

3. Tolerance Requirements: Tight tolerances increase setup precision and inspection time.

4. Surface Finish: Polishing, anodizing, or coating adds additional steps to the manufacturing process.

5. Order Volume: Larger batch production helps reduce the unit price through economies of scale.

Typical Cost Range of CNC Precision Metal Parts

Our experience at Shenzhen Zhihexing Electromechanical Co., LTD. shows that CNC Machining of Non-Standard Fasteners can range widely in price. The table below presents a general cost reference based on materials and part complexity.

| Material | Complexity Level | Tolerance | Estimated Unit Cost (USD) | Production Time |

| Aluminum 6061 | Low | ±0.05 mm | 2.50 – 5.00 | 1–2 days |

| Stainless Steel 304 | Medium | ±0.03 mm | 5.00 – 10.00 | 3–4 days |

| Brass | High | ±0.02 mm | 6.00 – 12.00 | 3–5 days |

| Titanium Alloy | High | ±0.01 mm | 10.00 – 25.00 | 5–7 days |

The Role of Design and Tolerance in Pricing

When customers send us drawings for CNC Machining of Non-Standard Fasteners, we evaluate design details such as internal threads, deep holes, or fine surface requirements. Each feature affects machining speed and tool wear. For instance, a part with ±0.01 mm tolerance requires slower feed rates and more measurement steps, increasing both cost and lead time. Our engineers always help clients optimize their design to balance performance with budget.

Material and Finishing Considerations

Material type and surface treatment are key contributors to total cost. At Shenzhen Zhihexing Electromechanical Co., LTD., our factory provides a wide selection of raw materials and finishes to meet industrial needs. CNC Machining of Non-Standard Fasteners may include optional treatments like anodizing, nickel plating, or sandblasting. Choosing the right finish not only enhances appearance but also protects parts against corrosion and wear, which is essential in high-precision applications.

How Our Factory Optimizes CNC Machining Costs

Over the years, our production team has developed an efficient workflow that ensures both precision and affordability. We use multi-axis CNC machines, automatic tool changers, and advanced simulation software to reduce idle time. Our quality control system includes dimensional inspection, hardness testing, and surface roughness evaluation. Shenzhen Zhihexing Electromechanical Co., LTD. is dedicated to providing clients with reliable CNC Machining of Non-Standard Fasteners at competitive prices, without compromising accuracy or consistency.

Frequently Asked Questions (FAQ)

1. How much do CNC precision metal parts cost per piece?

The price can vary from as low as $2.50 for simple aluminum components to over $25.00 for complex titanium parts. The main cost factors include material type, dimensional tolerance, and order volume. Our factory always provides a detailed quotation before production to ensure full transparency.

2. Does customization affect CNC machining costs?

Yes. Custom CNC Machining of Non-Standard Fasteners often involves unique tooling, fixtures, and additional setup time. Complex 3D contours, threaded holes, or surface treatments increase labor and machining time. Our engineers can help simplify certain design features to lower production expenses.

3. How can I reduce the overall cost of CNC precision parts?

Ordering in bulk, selecting cost-effective materials like aluminum, and relaxing non-critical tolerances are practical ways to save cost. At Shenzhen Zhihexing Electromechanical Co., LTD., our team reviews each drawing to suggest the most economical production solution while maintaining product functionality and durability.

Conclusion

The cost of CNC precision metal parts depends on many technical and economic variables. Understanding these factors helps manufacturers and buyers make informed decisions. With years of experience in CNC Machining of Non-Standard Fasteners, Shenzhen Zhihexing Electromechanical Co., LTD. ensures precise, efficient, and cost-effective solutions for every client. Whether for prototype development or mass production, our factory remains committed to delivering premium quality with reliable pricing and timely service.