How Often Should You Perform Maintenance On Conveyor Rollers

2025-09-01

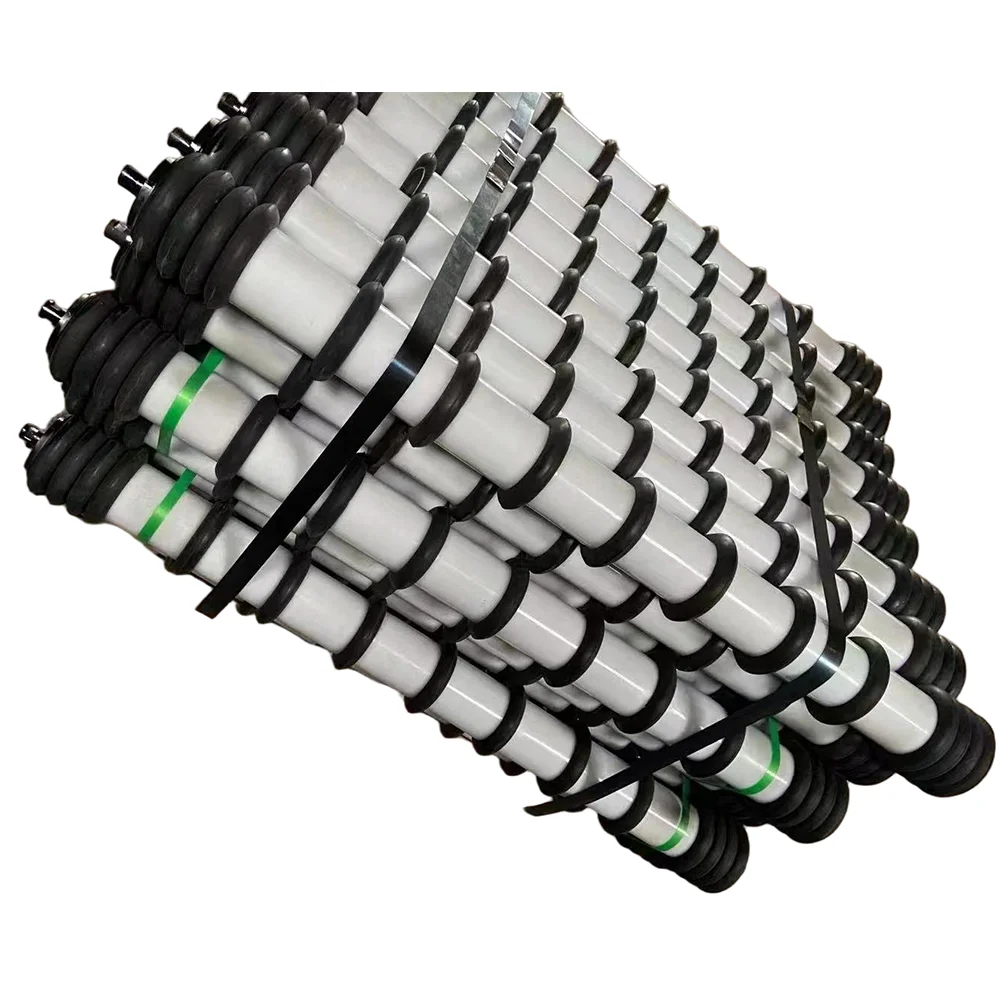

As an operations manager, you know that unplanned downtime is your biggest enemy. A critical yet often overlooked component is the Conveyor Roller. Proper maintenance isn't just a task—it's a strategy for maximizing productivity and minimizing cost. So, how often should you really be performing maintenance on your Conveyor Roller system? The answer isn't a simple number; it depends on a blend of factors we will explore.

What Factors Determine Conveyor Roller Maintenance Schedules

The ideal maintenance interval for your Conveyor Roller system is not one-size-fits-all. It is influenced by your specific operating environment and load demands.

-

Operational Environment: Exposure to extreme temperatures, moisture, dust, and corrosive materials can accelerate wear.

-

Load Capacity and Speed: Consistently running systems at or near their maximum load capacity or high speeds will require more frequent checks.

-

Material Handled: Abrasive materials (e.g., ore, gravel) cause more wear than non-abrasive ones (e.g., cardboard boxes).

A general guideline for visual inspections is weekly, with a more thorough physical inspection monthly. However, in harsh conditions, these intervals should be shortened.

What Are the Key Specifications of a Low-Maintenance Conveyor Roller

Investing in high-quality components from the start is the most effective way to extend maintenance intervals. Hipower engineers its rollers for durability and longevity, directly reducing your total cost of ownership.

| Feature | Hipower Specification | Benefit |

|---|---|---|

| Seal Type | Triple-Labyrinth Seal | Superior protection against dust and moisture ingress. |

| Bearing | Premium Grade Labyrinth Bearing | Pre-lubricated for life, requiring no maintenance. |

| Tube Material | Abrasion-Resistant Steel Coating | Withstands impact and reduces wear from abrasive materials. |

| Shaft | Hardened Steel, Precision Machined | Ensures perfect alignment and prevents seizing. |

Conveyor Roller FAQ

What are the first signs that a conveyor roller needs maintenance

The most common signs are unusual noise (grinding or rumbling), visible rust or corrosion on the Conveyor Roller, and irregular roller rotation or complete seizure. You may also notice material spillage or belt misalignment caused by a failing roller.

Can improper installation affect how often maintenance is needed

Absolutely. Incorrect installation, such as using excessive force during fitting or improper alignment, can put premature stress on the bearings and seals of the Conveyor Roller. This leads to faster degradation and a higher risk of unexpected failure, necessitating more frequent maintenance.

Why do some rollers fail much earlier than their rated lifespan

Early failure is almost always caused by operating outside the specified parameters. This includes overloading the system, exposure to unplanned contaminants like corrosive chemicals, or using a Conveyor Roller not rated for the specific environment (e.g., using a standard roller in a wash-down food processing area).

Proactive maintenance is the key to unlocking maximum efficiency from your operations. By partnering with Hipower, you gain access to engineered components designed for reliability and long service intervals.

Contact us today for a free, no-obligation audit of your conveyor system. Let our experts help you build a customized maintenance schedule that boosts your uptime and protects your bottom line.