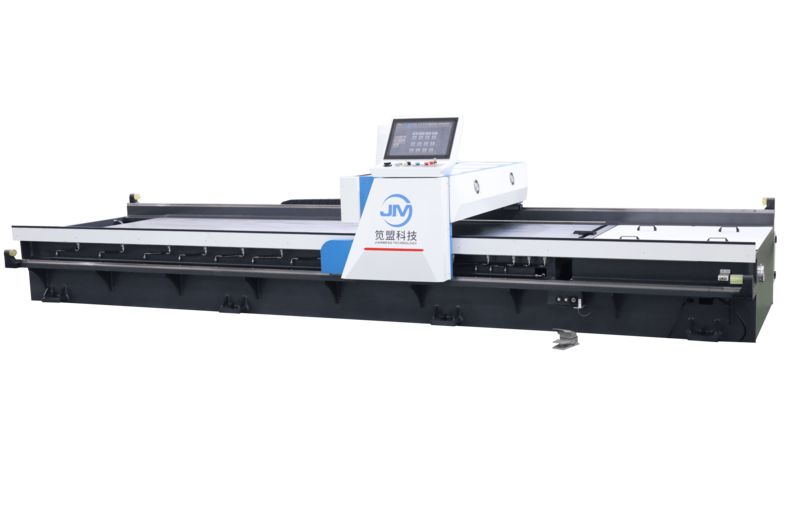

How to Choose the Application Scenario of Horizontal High Speed V Grooving Machine

2025-07-25

Speaking of high-speed V-groove machines, they are a good helper for industries such as packaging, printing, and electronics. But choosing the right model is not an easy task. It depends on where it is used, what materials to be processed, and how high the precision requirements are. Today, let's talk about this matter in detail.

1. How to choose in the luggage and paper box industry Friends who make corrugated paper boxes and gift boxes use this machine most often. This industry emphasizes speed, accuracy, and stability. Generally, a medium- and high-speed model that can run 60-80 meters per minute is enough. But pay attention to the thickness of the cardboard. Choose an ordinary model for 3-5mm, and a heavy machine for more than 7mm. Now it is popular with automatic deviation correction function, which is particularly convenient for making special-shaped paper boxes.

2. Special needs of printing and packaging Color boxes, tobacco and alcohol packaging, which have high precision requirements, must be selected with CCD positioning system. This machine can be accurate to 0.1mm, and is particularly suitable for hot stamping and UV processes. For the recently popular small-batch customized packaging, choosing a model with a quick tool change function can save a lot of time.

3. Special scenarios in the electronics industry For precision processing of circuit boards and insulating materials, you need to use models with dustproof design. It is best to choose a machine with a dust suction device, otherwise it will be troublesome if debris falls into it. For FPC flexible circuit boards, choose one with adjustable pressure to avoid crushing the materials.

4. Precautions for other industries For wooden packaging, pay attention to the material of the tool. Tungsten carbide is much more durable than high-speed steel. For plastic products, you need to choose a machine with a cooling system, otherwise the material is easy to deform. Now the new smart models can also monitor production data online, which is suitable for manufacturers who want to build smart workshops.

The most taboo thing when choosing a high-speed V-groove machine is "big and complete". It depends on your actual needs. Don't listen to the sales' nonsense. Configurations that don't use any functions are a waste of money. First figure out what materials you want to process, how much you want to produce per day, and how high the precision requirements are, and then look at the machine parameters. Remember, the most suitable one is the best.

As a professional manufacturer and supplier, we provide high-quality products. If you are interested in our products or have any questions, please feel free to contact us.