Introduction of Sheet Equipment

2025-06-10

Sheet equipment generally refers to the tools, machinery, and instruments used in the manufacturing, handling, or processing of sheet materials. These materials can be metals, plastics, wood, or other substances that are processed in flat, thin forms. The equipment helps with cutting, shaping, bending, or welding these sheets into various forms for industrial or commercial use.

Here are some common types of sheet equipment:

1. Sheet Metal Equipment

Shears: Machines used for cutting sheet metal into straight lines or curves.

Press Brake: A machine that bends sheet metal by pressing it between a punch and a die.

Laser Cutters: Use focused lasers to cut intricate patterns or shapes into sheet metal.

Plasma Cutters: High-temperature tools that use plasma to cut through conductive metals.

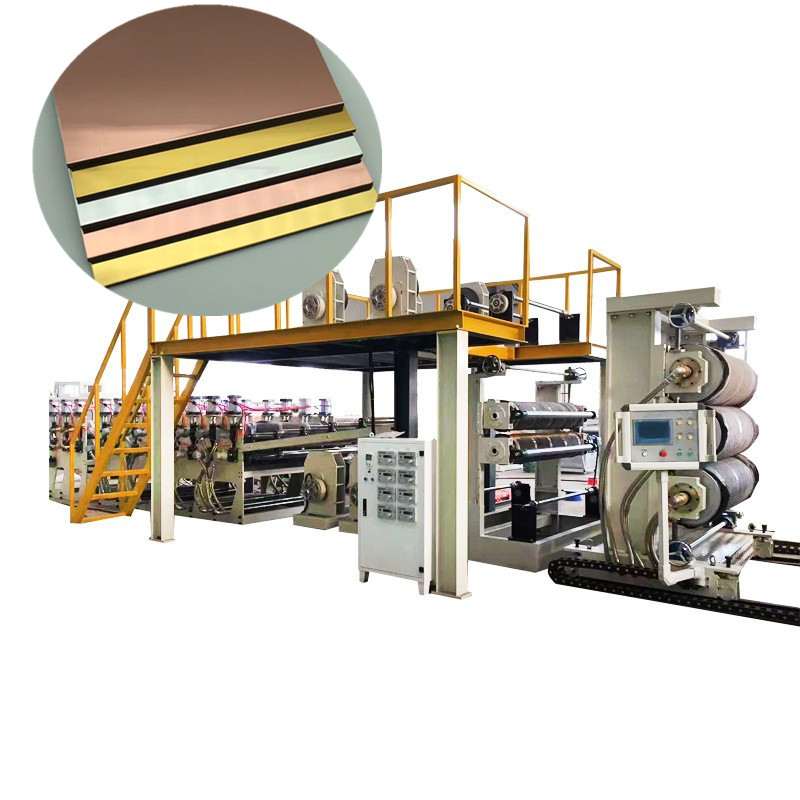

Roll Forming Machines: Machines that continuously bend sheet metal into a desired profile.

2. Woodworking Equipment for Sheets

Panel Saws: Used for cutting large sheets of wood into smaller pieces.

CNC Routers: Computer-controlled machines used for cutting, carving, or shaping sheet materials like wood or plastic.

Edge Banding Machines: Apply a finishing edge to the exposed sides of sheet wood.

3. Plastic Sheet Equipment

Vacuum Forming Machines: Use heat and vacuum to mold plastic sheets into specific shapes.

Extruders: Machines that push plastic sheets through molds to form continuous shapes.

Cutting Machines: Specialized tools to cut plastic sheets into specific dimensions.

4. Fabric Handling Equipment

Fabric Rollers: Used for feeding fabric sheets into various machines.

Fabric Cutters: Devices like rotary cutters or lasers used to cut fabric sheets to the desired size.

Laminating Machines: Used to bond sheets of material together for enhanced durability or design.

5. Storage and Handling Equipment

Sheet Racks: For storing and organizing sheets in a warehouse or workshop.

Hoists and Cranes: Used to move large, heavy sheets safely.

6. Quality Control Equipment

Thickness Gauges: To measure the thickness of sheet materials accurately.

Surface Finish Testing Machines: Ensure the surface of the sheet is smooth and free from defects.

These types of sheet equipment help optimize the processing of raw materials, improving efficiency and quality in various industries such as manufacturing, construction, automotive, and more.

If you are interested in our products or have any questions, please feel free to contact us.