The Versatility and Importance of Adhesive Labels

2024-09-13

Adhesive labels are a crucial component in modern packaging, product identification, and logistics. From the tiny sticker on a fruit at the supermarket to the barcode on a product in a warehouse, adhesive labels are used across a wide range of industries to convey vital information quickly and efficiently. These labels are more than just tags—they are essential tools for communication, branding, and inventory management.

In this blog, we'll explore the different types of adhesive labels, their applications, and the benefits they bring to businesses and consumers alike.

What Are Adhesive Labels?

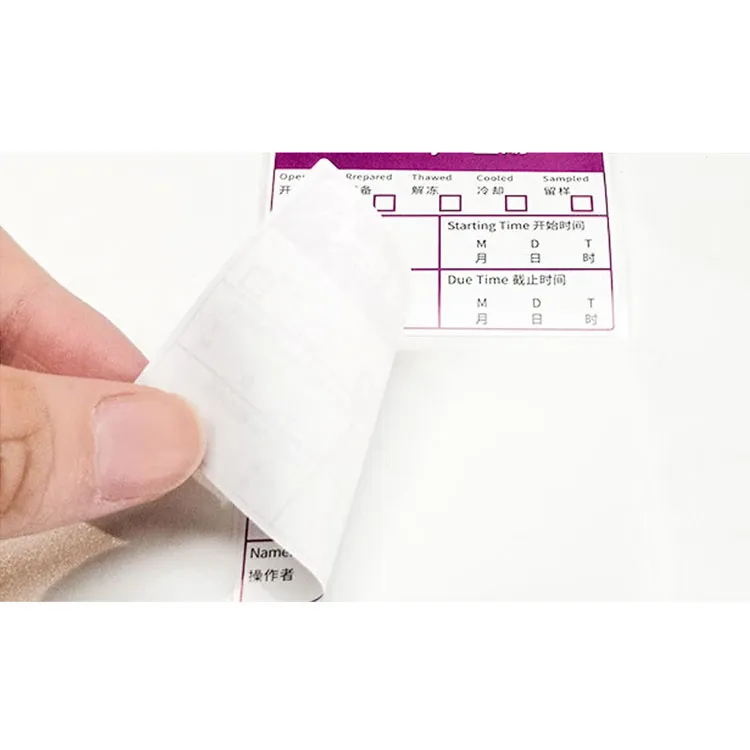

Adhesive labels are small pieces of material, usually paper, plastic, or fabric, with a sticky backing that allows them to adhere to surfaces. The adhesive can be permanent or temporary, depending on the intended application. These labels are commonly used to display information such as product names, prices, barcodes, safety instructions, and promotional messages.

Adhesive labels are designed for easy application and are often customizable to fit the specific needs of a product, company, or industry.

Types of Adhesive Labels

1. Pressure-Sensitive Labels

Pressure-sensitive labels are the most common type of adhesive label. They have a sticky surface that adheres to most materials with the application of light pressure. There is no need for heat, water, or solvents, making them easy to use in a variety of settings.

These labels are highly versatile and can be found on everything from food packaging to shipping boxes. They are available in both permanent and removable forms, making them ideal for applications where labels may need to be removed or repositioned without leaving residue.

2. Heat-Sensitive Labels

Heat-sensitive or thermal labels are another popular type of adhesive label, especially in industries where durability and reliability are crucial. These labels are printed using a thermal printer, which applies heat to create text or images. They are commonly used in shipping, logistics, and retail environments due to their cost-efficiency and ability to withstand harsh conditions.

Thermal labels come in two types: direct thermal, where heat creates the print on the label, and thermal transfer, where heat transfers ink from a ribbon onto the label. Both types are durable, resistant to fading, and ideal for high-volume applications.

3. Water-Activated Labels

Water-activated adhesive labels require moisture to activate the adhesive backing. These labels are typically used in applications where a strong, permanent bond is needed. For example, water-activated labels are common in packaging for large boxes or items that need to be secured during shipping.

Once applied, these labels are difficult to remove, making them perfect for tamper-proof seals and security purposes.

4. Self-Adhesive Labels

Self-adhesive labels are pre-coated with adhesive and are ready to be applied once the backing paper is removed. They are available in a wide range of materials, shapes, and sizes and are suitable for many applications, including labeling glass bottles, jars, envelopes, and more.

These labels are often used in the food and beverage industry, as well as for product labeling, where a durable and reliable adhesive is necessary.

5. Removable Adhesive Labels

Removable adhesive labels are designed to be easily peeled off without leaving residue. These labels are ideal for temporary labeling needs such as promotions, sales, or seasonal products. They can also be used in retail settings, where price tags or promotional stickers need to be changed frequently.

The key benefit of removable labels is that they don’t damage the surface of the product when removed, which is crucial for maintaining product appearance.

Applications of Adhesive Labels

1. Product Identification

One of the most common uses of adhesive labels is for product identification. Whether it's a small bottle of medicine or a large appliance, adhesive labels are used to provide essential information such as brand name, product details, ingredients, and expiration dates.

In the retail world, labels are often used to differentiate between similar products and help consumers make informed purchasing decisions. For instance, food packaging labels include nutritional information and ingredient lists, allowing shoppers to choose items based on dietary needs or preferences.

2. Branding and Marketing

Adhesive labels are also powerful tools for branding and marketing. Custom labels that feature a company’s logo, color scheme, and unique design can help make a product stand out on store shelves and attract customers. Labels can be used for promotional purposes, such as limited-time offers, discounts, or “buy one, get one” deals.

For businesses, using adhesive labels as part of their packaging design helps reinforce brand identity and build consumer recognition. Eye-catching, well-designed labels can leave a lasting impression and drive customer loyalty.

3. Inventory and Logistics

In warehouses and shipping facilities, adhesive labels play a critical role in inventory management. Barcode labels, for example, allow for quick and efficient tracking of goods as they move through the supply chain. These labels help workers identify items, manage stock levels, and ensure the correct products are shipped to the right locations.

Labels used in logistics often feature barcodes, QR codes, or RFID technology to enable real-time tracking and data collection, making it easier for businesses to monitor their inventory and reduce errors.

4. Safety and Compliance

Adhesive labels are also used to convey safety warnings and compliance information. In industries such as chemicals, pharmaceuticals, and manufacturing, labels are necessary to provide hazard warnings, usage instructions, and regulatory information. These labels ensure that products are handled safely and in accordance with legal standards.

Labels that display important information about allergens, flammable materials, or disposal instructions help protect consumers and workers while promoting adherence to industry regulations.

Benefits of Adhesive Labels

1. Cost-Effective

Adhesive labels are a cost-effective solution for labeling products and packages. Compared to other methods of product identification, such as engraving or embossing, adhesive labels are much cheaper to produce and apply. This makes them a popular choice for businesses of all sizes.

2. Customizable

Adhesive labels can be fully customized to meet the specific needs of a product or business. From choosing the right material and adhesive type to incorporating branding elements, businesses have full control over the design and functionality of their labels.

Custom labels allow businesses to communicate product information effectively while reinforcing their brand identity.

3. Easy to Apply

Adhesive labels are simple to apply, whether manually or using automated equipment. Their ease of use makes them ideal for high-speed production environments, where efficiency is key.

With options like peel-and-stick labels or machine-applied solutions, businesses can streamline their labeling process without sacrificing quality.

4. Versatile

Adhesive labels can adhere to a wide range of surfaces, including glass, plastic, metal, and fabric. This versatility means they can be used in various industries, from food and beverage packaging to clothing tags, shipping labels, and industrial equipment.

Conclusion

Adhesive labels are an indispensable tool for product identification, branding, and logistics management. Their versatility, affordability, and ease of use make them a preferred choice for businesses across various industries. Whether it's for conveying critical product information, ensuring regulatory compliance, or enhancing brand visibility, adhesive labels offer a flexible and efficient solution that meets the demands of modern commerce.

As technology continues to evolve, adhesive labels will likely incorporate even more advanced features, such as smart labels and environmentally friendly materials, further expanding their role in product packaging and communication.