What Exactly is an Automatic Condenser Evaporator Header Pipe and Why is it a Game-Changer?

2025-09-04

In the intricate world of heat exchange systems, every component plays a pivotal role. But one innovation that consistently captures my attention for its profound impact on system efficiency and reliability is the Automatic Condenser Evaporator Header Pipe. At its core, this isn't just another pipe; it's an intelligent distribution system designed to revolutionize how refrigerant is managed within condensers and evaporators.

What Does It Do?

The primary role of an Automatic Condenser Evaporator Header Pipe is to ensure the perfect and automatic distribution of refrigerant. In traditional systems, uneven refrigerant flow can lead to inefficiencies, such as some tubes being flooded while others are starved. This intelligent header pipe automatically balances the flow, ensuring each individual heat transfer tube receives the precise amount of refrigerant required for optimal phase change and heat absorption or rejection. It acts as the central nervous system for distribution, responding dynamically to changing load conditions.

What Are the Usage Effects?

Upgrading to a system equipped with an automatic header pipe delivers immediate and significant advantages. We have consistently observed the following outcomes in our clients' operations:

-

Maximized Heat Transfer Efficiency: Eliminates maldistribution, ensuring every tube contributes to its full potential.

-

Enhanced System Capacity: Systems can achieve higher cooling or heating capacities without increasing the physical footprint.

-

Significant Energy Savings: By optimizing performance, compressors work less, leading to a direct reduction in power consumption.

-

Improved System Reliability: Prevents issues like liquid slugging and oil trapping, reducing wear and tear and extending the equipment's lifespan.

-

Reduced Frosting in Evaporators: Promotes even defrosting cycles, maintaining consistent performance in low-temperature applications.

These effects directly translate into lower operational costs and a stronger return on investment.

Why Can't You Ignore It?

Ignoring the quality of your header pipe is like ignoring the foundation of a building. Its importance cannot be overstated. A poorly functioning distribution system cripples the entire heat exchanger, no matter how advanced the tubes or fins are. It is the key to unlocking the true, designed performance of your condenser or evaporator. For my team, it is the first component we analyze when aiming to boost a system's overall coefficient of performance (COP).

Frequently Asked Questions

Q: How does the Automatic Condenser Evaporator Header Pipe achieve this automatic distribution?

A: Its internal design features specialized orifices and a pressure-balancing mechanism. It self-regulates, allowing more refrigerant to flow to pathways with higher pressure drop and less to those with lower resistance, creating a perfect equilibrium.

Q: Can this header pipe be retrofitted into existing systems?

A: Absolutely. While designed for new OEM installations, our engineering team can often design custom solutions for retrofitting older systems, providing a cost-effective path to a performance upgrade.

Q: What materials are available to ensure compatibility with different refrigerants?

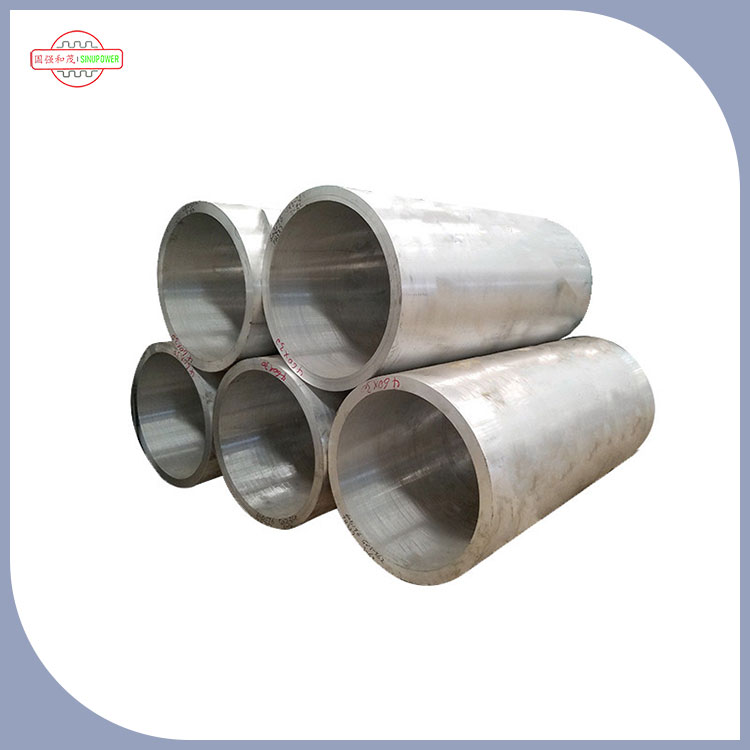

A: We manufacture Automatic Condenser Evaporator Header Pipes from a variety of materials to meet any application need, including copper, brass, and stainless steel, ensuring compatibility with all common and next-generation refrigerants.

| Feature | Benefit | Impact |

|---|---|---|

| Automatic Flow Regulation | Self-balancing refrigerant distribution | Maximized efficiency and capacity |

| Robust Construction | High-quality copper/brass alloys | Long service life and corrosion resistance |

| Precision Engineering | Perfectly sized orifices and chambers | Consistent performance under variable loads |

| Customizable Design | Tailored to specific system requirements | Optimal integration and performance |

In conclusion, the decision to integrate a high-quality Automatic Condenser Evaporator Header Pipe is a decisive step toward peak system performance, remarkable energy savings, and unparalleled reliability. It is an investment that pays for itself. We at Sinupower Heat Transfer Tubes Changshu Ltd. are passionate about providing this critical component, engineered to the highest standards. Contact us today to discuss how we can optimize your heat exchange systems.