What is Open Type Fiber Laser Cutting Machine

2025-06-11

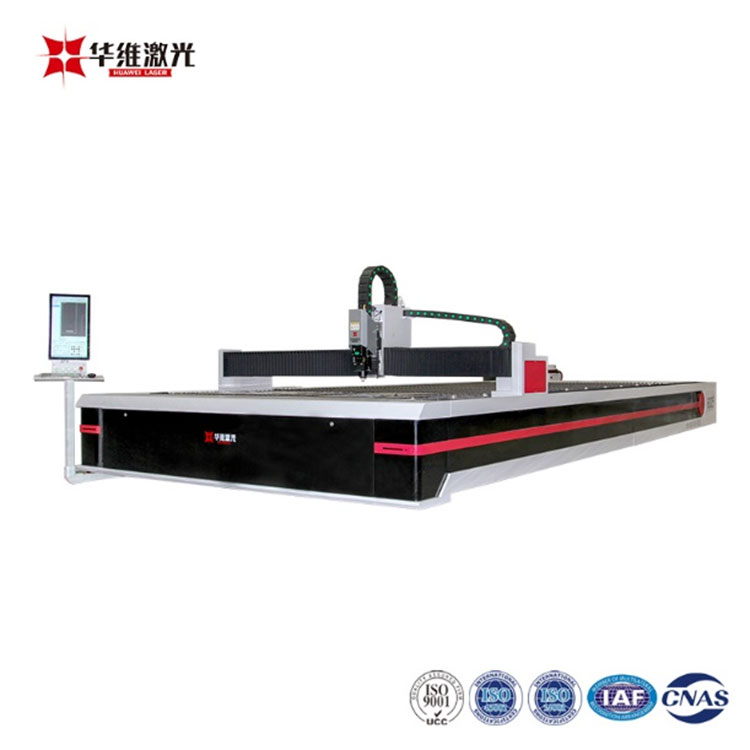

An Open Type Fiber Laser Cutting Machine is a type of laser cutting system designed for precise and high-speed cutting of metals and other materials. The "open type" refers to the machine's design, where the cutting area is not enclosed by a cover or protective housing, making it more accessible for loading and unloading materials.

Here’s a breakdown of its key features:

Fiber Laser Technology: This machine uses a fiber laser, which is more efficient than traditional CO2 lasers. Fiber lasers offer high beam quality, longer lifespan, and lower maintenance costs.

Open Design: Unlike closed machines, which have fully enclosed workspaces for safety, an open-type machine allows easy access to the cutting area. Operators can load and unload materials more freely, which is ideal for small to medium-sized production.

Precision: It is known for its high precision in cutting various metals, including stainless steel, aluminum, brass, and mild steel. It delivers clean cuts with minimal heat distortion.

Speed: Fiber laser cutting machines are faster than conventional CO2 laser cutters, thanks to the high efficiency of the fiber laser beam.

Versatility: These machines can cut thin to thick materials with high-quality results, and they can be used for a wide range of industries, such as automotive, aerospace, and metal fabrication.

Applications: It's commonly used in cutting flat sheet materials but can be adapted for tube cutting as well, depending on the machine's configuration.

The open type design makes these machines more flexible for different production scenarios, though they may not provide the same level of safety as fully enclosed systems. Operators typically need to follow specific safety protocols.

If you are interested in our products or have any questions, please feel free to contact us.