What Makes the Upward Expansion Discharge Valve Essential?

2025-09-04

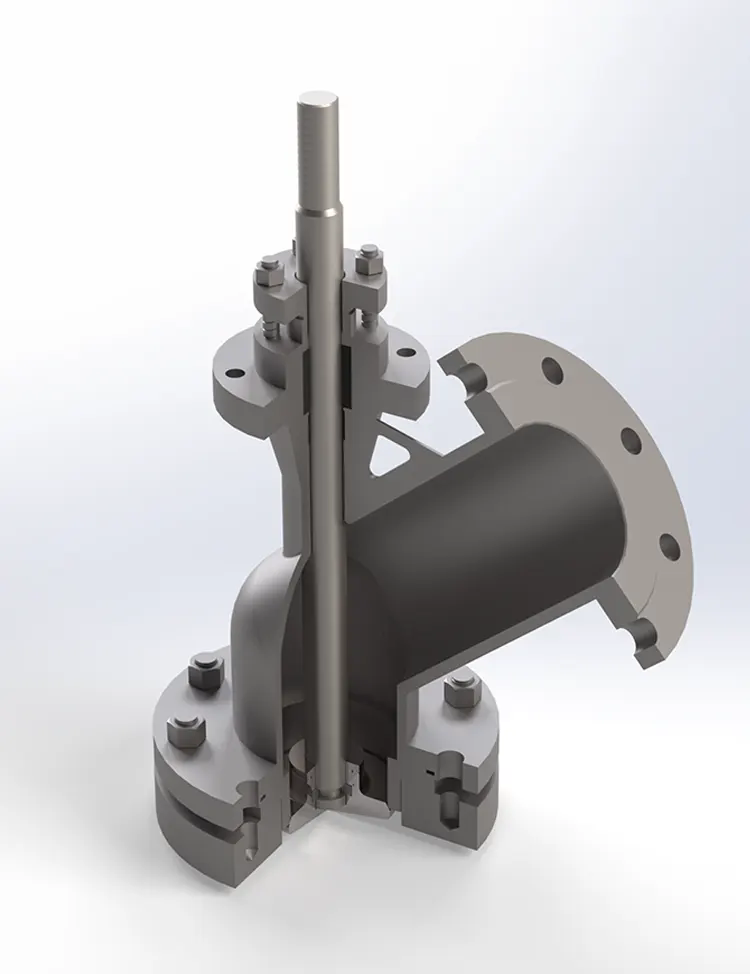

In today’s demanding industrial environment, efficiency, precision, and durability are key factors in selecting components for fluid control systems. One such critical component is the Upward Expansion Discharge Valve, a specialized valve engineered to handle high-pressure discharge operations with exceptional reliability and performance. From petrochemical plants to power stations and heavy-duty manufacturing, this valve plays a vital role in ensuring system safety, improving operational efficiency, and reducing maintenance downtime.

Understanding the Upward Expansion Discharge Valve

The Upward Expansion Discharge Valve is a high-performance industrial valve designed to control the release of pressurized fluids or gases from storage tanks, pipelines, or process vessels. Its innovative upward expansion mechanism ensures consistent sealing performance, minimizes energy loss, and maintains system safety under fluctuating pressure conditions.

How It Works

Unlike conventional discharge valves, the upward expansion design allows the valve disc to expand upward against the flow direction when opened. This mechanism ensures smoother fluid release and prevents turbulence, thereby enhancing the valve’s efficiency and reducing wear on internal components.

Key functions include:

-

Precise Pressure Control – Regulates fluid or gas discharge to maintain optimal system balance.

-

Enhanced Sealing – The expansion mechanism achieves a superior seal, even in high-pressure environments.

-

Extended Service Life – Reduces mechanical stress, resulting in lower wear and longer operational life.

Core Benefits

-

Improved energy efficiency due to reduced fluid resistance.

-

High reliability in extreme temperature and pressure conditions.

-

Low maintenance requirements thanks to advanced sealing technology.

-

Compatibility with diverse fluids including water, oil, steam, gas, and corrosive chemicals.

Technical Specifications of Upward Expansion Discharge Valve

When selecting an Upward Expansion Discharge Valve, understanding its technical parameters is crucial. Below is an overview of standard specifications for industrial-grade models:

| Parameter | Specification |

|---|---|

| Valve Type | Upward Expansion Discharge Valve |

| Material | Stainless Steel, Carbon Steel, Alloy Steel |

| Nominal Diameter | DN50 – DN1200 |

| Pressure Rating | PN10 – PN250 / Class 150 – Class 1500 |

| Temperature Range | -40°C to +600°C |

| Sealing Type | Metal-to-Metal / Soft Sealing Options |

| Connection Type | Flanged, Welded, or Threaded |

| Operation Method | Manual, Electric, Pneumatic, or Hydraulic |

| Flow Media | Liquids, Steam, Gas, Corrosive Chemicals |

| Standards Compliance | API, ASME, ISO, DIN |

This level of engineering flexibility allows the Upward Expansion Discharge Valve to perform seamlessly across various industrial setups, ensuring optimal control, minimal leakage, and long-lasting durability.

Applications and Performance Advantages

The Upward Expansion Discharge Valve is widely used in high-demand industries where reliable fluid control is critical. Its unique design and durability make it a preferred choice for systems where performance and safety cannot be compromised.

Primary Application Sectors

-

Petrochemical Industry – For handling high-temperature and high-pressure chemical flows.

-

Power Generation – Used in steam discharge systems, cooling circuits, and condensate management.

-

Oil & Gas – Suitable for upstream, midstream, and downstream processes.

-

Water Treatment Facilities – Ensures controlled release of treated water or wastewater.

-

Pharmaceutical and Food Processing – Guarantees safe, clean discharge control under hygienic conditions.

Why Choose an Upward Expansion Discharge Valve?

Compared to conventional discharge valves, upward expansion models offer significant operational advantages:

-

Superior Flow Control – Smooth upward expansion eliminates sudden pressure drops.

-

Safety Enhancement – Prevents backflow and leakage under high-pressure scenarios.

-

Corrosion Resistance – Advanced material options extend valve life in aggressive environments.

-

Energy Optimization – Reduces energy consumption by lowering fluid friction.

-

Reduced Maintenance Costs – Fewer mechanical failures result in lower long-term expenses.

By integrating these valves into industrial pipelines, businesses can significantly improve process efficiency, reduce operational risks, and achieve a higher return on investment.

FAQs on Upward Expansion Discharge Valve

To further clarify its functionality and benefits, here are two commonly asked questions:

Q1. How does the Upward Expansion Discharge Valve improve system efficiency?

A1. The upward expansion design allows smoother fluid discharge by reducing turbulence and pressure fluctuations. This results in less energy loss during operation, enhanced sealing integrity, and improved control accuracy. The valve also requires less frequent maintenance, further optimizing overall system performance and reducing operational costs.

Q2. What factors should be considered when selecting an Upward Expansion Discharge Valve?

A2. When choosing the right valve, consider the following factors:

-

System Pressure & Temperature – Ensure compatibility with your operational environment.

-

Media Type – Verify material compatibility with liquids, steam, gas, or corrosive fluids.

-

Flow Rate Requirements – Select the appropriate nominal diameter to handle the system’s capacity.

-

Actuation Method – Choose between manual, pneumatic, electric, or hydraulic operation based on control needs.

-

Standards & Certifications – Ensure compliance with international industry standards for safety and reliability.

Why LOZOSE is Your Trusted Partner

Choosing the right Upward Expansion Discharge Valve can significantly influence your system’s efficiency, safety, and operational costs. At LOZOSE, we specialize in delivering high-performance valves engineered to meet the most demanding industrial requirements. Our valves are manufactured using premium-grade materials, advanced sealing technologies, and strict quality control processes to ensure maximum reliability and longevity.

With decades of experience in industrial valve solutions, LOZOSE provides not only top-tier products but also expert technical guidance and tailored support to meet your specific project needs.

If you are looking for Upward Expansion Discharge Valves that guarantee exceptional quality and performance, contact us today to learn how LOZOSE can help optimize your systems.