Why Are MDR Conveyor Rollers More Efficient Than Traditional Systems

2025-09-01

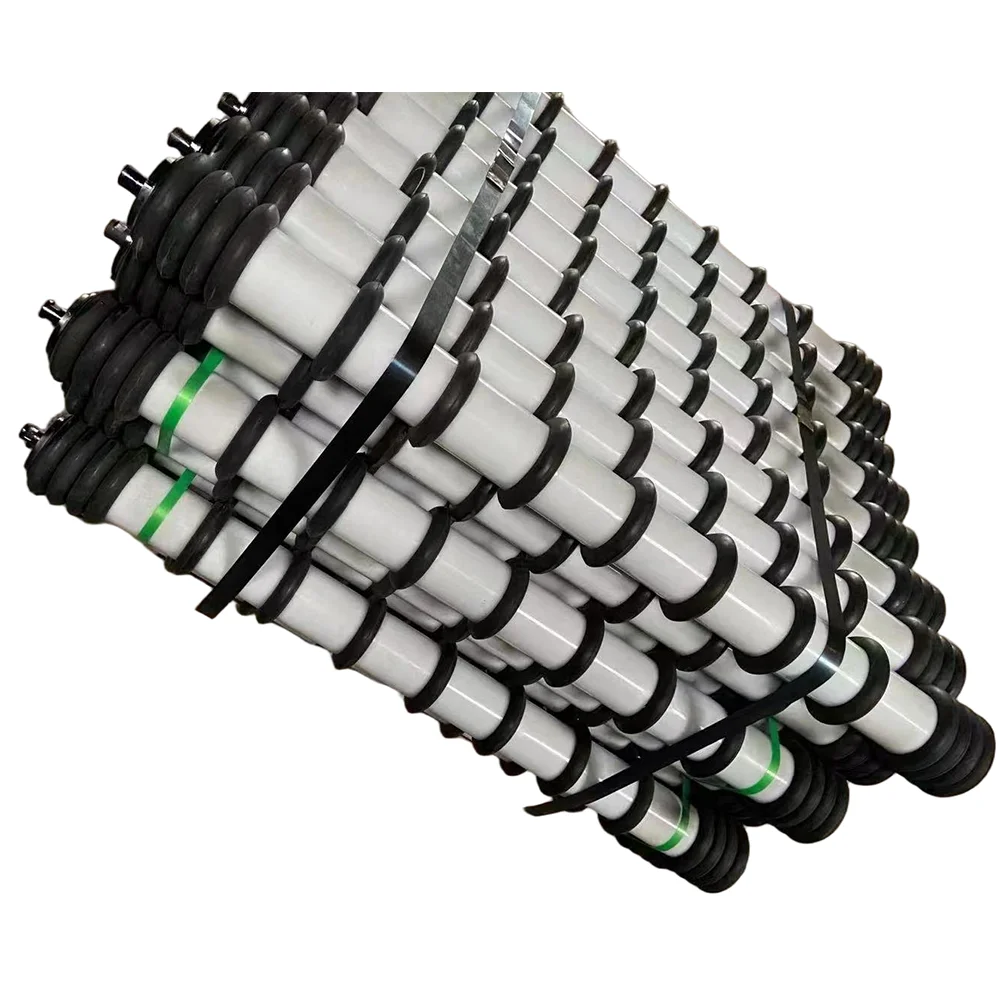

For decades, facilities relied on traditional conveyor systems that were often noisy, energy-intensive, and complex to maintain. The emergence of MDR Conveyor Rollers (Motorized Drive Rollers) represents a significant leap in efficiency and operational intelligence. But what makes them truly superior?

Unlike traditional systems that use a single, central motor, MDR systems feature a brushless DC motor inside each roller. This on-demand, zoned drive approach eliminates the need for complex external drives, belts, and chains. The result is a drastic reduction in energy consumption—often by up to 70%—as only the rollers under active load need to be powered. Furthermore, their quiet operation and reduced mechanical complexity lead to lower maintenance costs and enhanced system flexibility.

Hipower engineers have refined this technology, ensuring our MDR Conveyor Roller systems deliver unmatched reliability and performance for modern material handling needs.

What Are the Key Technical Advantages of MDR Rollers

The efficiency of an MDR Conveyor Roller system is quantified in its specifications. Hipower MDR rollers are designed for maximum performance and longevity.

Key Product Parameters:

-

Voltage Options: 24V DC and 48V DC for safe and efficient operation.

-

Speed Range: 20 to 120 feet per minute, offering precise control.

-

Load Capacity: Standard models support up to 125 lbs per roller, with heavy-duty options available.

-

Noise Level: Typically less than 50 dB, creating a quieter work environment.

-

IP Rating: IP54 sealing protects against dust and water ingress, ensuring durability.

| Feature | Hipower MDR Roller | Traditional Roller System |

|---|---|---|

| Energy Consumption | Low (Zoned power) | High (Constant central motor run) |

| Maintenance Needs | Minimal (No belts, chains, or external gears) | Frequent (Belt tensioning, lubrication) |

| Noise Level | < 50 dB (Quiet) | Often > 70 dB (Noisy) |

| Control Flexibility | High (Individual zone control) | Low (Limited control options) |

| Installation | Simple and quick | Complex and time-consuming |

MDR Conveyor Roller FAQ

What is the typical lifespan of an MDR Conveyor Roller

A high-quality MDR Conveyor Roller, like those from Hipower, is designed for a long service life, often exceeding 30,000 hours of operation. Their brushless motor design and sealed bearings minimize wear, ensuring reliability over many years.

Can MDR rollers be integrated into existing conveyor frames

Yes, one of the major advantages of MDR Conveyor Roller technology is its retrofit capability. Hipower offers models designed to fit common industry frame sizes, making it straightforward to upgrade traditional systems to modern, efficient MDR technology without a complete overhaul.

How do MDR systems improve control and accumulation

MDR systems enable zero-pressure accumulation. Each zone can independently start and stop, allowing products to accumulate without touching each other, which prevents damage. Hipower systems integrate seamlessly with programmable logic controllers (PLCs) for sophisticated and smooth operation.

Upgrading to an MDR Conveyor Roller system from Hipower is an investment in reduced operating costs, enhanced flexibility, and future-proof technology.

Contact us today to schedule a free efficiency consultation and discover how our MDR solutions can transform your operation.