Home > Products > Woodworking Machinery > Wood Based Panel Machine > 15 Layers Full Automatic Plywood Hot Press Machine

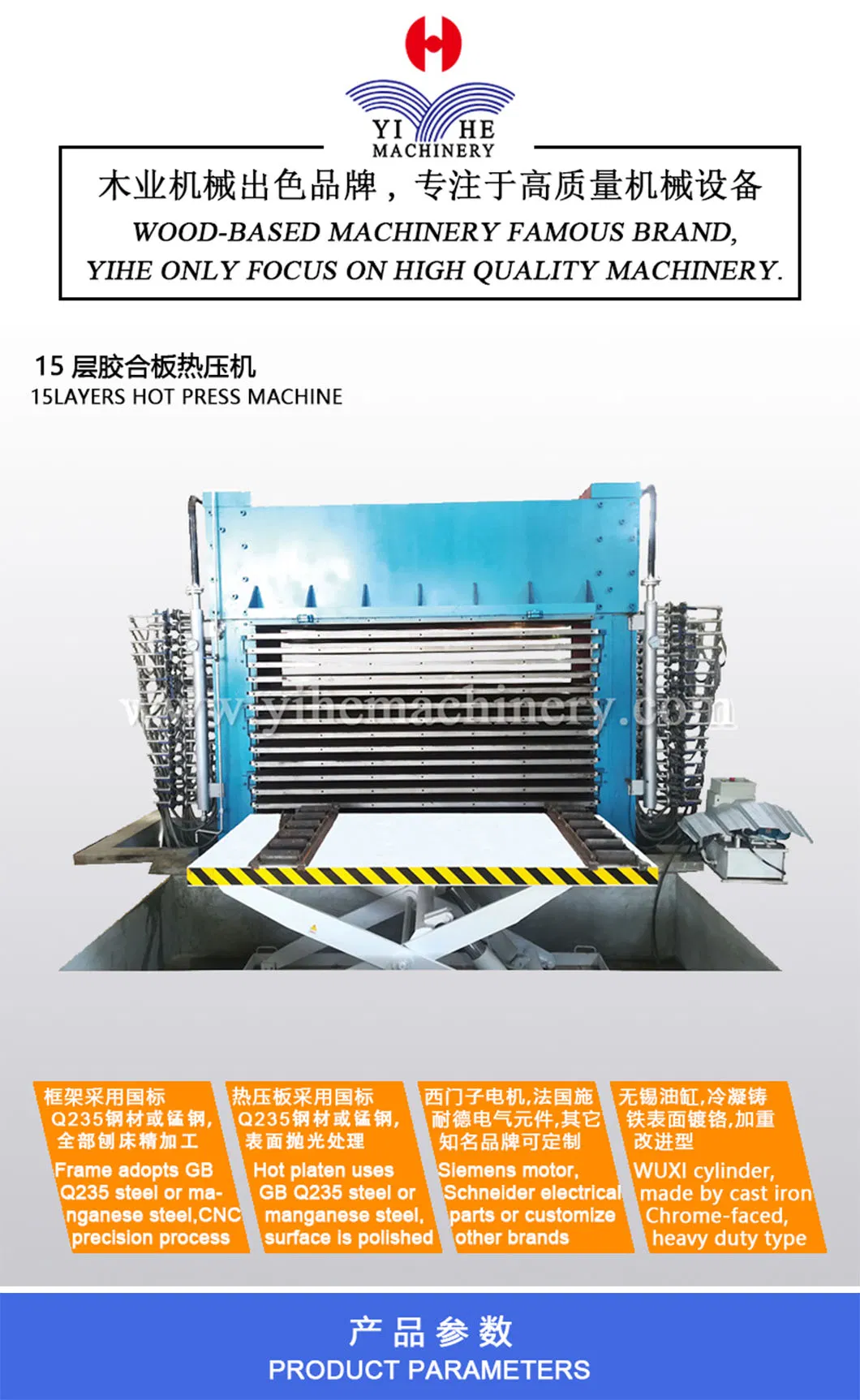

15 Layers Full Automatic Plywood Hot Press Machine

Model Number:YHHPR-50-15ANominal pressure:500TLayers:15Boards inlet method:TransverseOpening distance:70mmQuantity of hot platens:16Size of hot platen:1370*2700*42mmHot platen inside pipeline:Two inlets and two outletsQuantity of cylinders:2pcsDiameter of main cylinders:360mmWorking stroke of cylind......

Send Inquiry

Product Description

| Model Number: | YHHPR-50-15A |

| Nominal pressure: | 500T |

| Layers: | 15 |

| Boards inlet method: | Transverse |

| Opening distance: | 70mm |

| Quantity of hot platens: | 16 |

| Size of hot platen: | 1370*2700*42mm |

| Hot platen inside pipeline: | Two inlets and two outlets |

| Quantity of cylinders: | 2pcs |

| Diameter of main cylinders: | 360mm |

| Working stroke of cylinders: | 1050mm |

| Allowed pressure: | <=25Mpa |

| Closing time of no-loading: | 15-18seconds |

| Flow of low pressure pump: | 250*2pcs |

| Allowed pressure: | 3Mpa |

| Motor power : | 15kw*2pcs |

| Flow of high pressure pump: | 25 |

| Allowed pressure: | 25Mpa |

| Power of motor: | 7.5kw |

| Dimension: | 3700*1370*4960mm |

| Controlling methods: | Automatic hydraulic stations |

| Hydraulic station brand: | Wuxi brand |

| Thickness of up and down column: | 900mm |

| Main steel plate thickness: | 35mm |

| Total weight of this machine: | 34t |

| Heating medium: | Thermal oil |

| Controller electrical parts: | Delta,Schneider,Siemens PLC, Siemens Touching Screen |

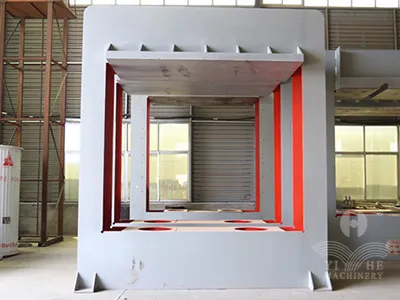

| 1. CNC Planer Precision Process Frame Frame is made by CNC planer precision process, To make sure plywood thickness accuracy and uniform. The frame uses GB Q235 steel or Manganese steel. Steel thickness is calculated according to machine pressure. 500T usually pressure steel thickness is 35mm. |  |

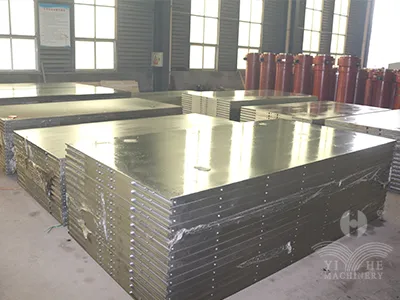

| 2. Polishing Hot Platen The hot platen is after polishing, very smooth and high accuracy. Thermal oil double inlet and double outlet huge heating energy and quick transfer. Thickness error is less than 1mm, heating transfer uniform and surface temperature error is very less. |

| 3. WUXI Chrome-faced Cylinder WUXI brand cylinder, chrome-faced, anti-rust treatment, iron cast and heavy duty. 360mm diameter cylinder of hot press machine weight is 1.9T. |  |

| 4. Silent Dustproof Hydraulic Station Hydraulic station uses TAIWAN hydraulic technology. It uses Siemens brand motor,, KINYUN solenoid valve, TAIWAN HEANG hydraulic pump. It has slient, dustproof and no-maintance advantage. |

| 5. DELTA Full Automatic PLC System The control cabinet adopts TAIWAN DELTA full automatic PLC system, the machine runs automatically, operation easily. It uses France Schneider brand electrical parts. And allow customize other brand according to client's requirement. |  |

Shandong Linyi Jianye Shunda Machinery Co., Ltd.(formerly Linyi Jianye Machinery Factory)founded in 1991, is a set of production, sales, service, reach and development as one of the multi-company and multi-category professional manufacturers of wood machinery, It is a modern management services company, under the construction industry Shunda Machinery Manufactur of Zhu Bao Branch, Jianye Rubber Products Factory and Jinze import and Export Co., Ltd.

After more than 20 years of continuous development and growth, under the sincere cultivation of the vast number of customers and the joint efforts of all the employees of the company, Now we have the brand of "Yihe" and six categories of series.Glue spreader machine series, drying machine series, hot press machine series, sawing machine series, in the patchwork (scraper) series and rubber products series.Become more than 40 kinds of products of large and medium-sized wood machinery professional manufacturers.

The company always adheres to the service aim of the brand, high efficiency, honesty and pragmatism, and sincerely expects to cooperate, develop and progress with domestic and foreign businessmen.With sophisticated equipment, advanced processing technology and perfect testing methods, the company continuously improves its technical level and strives to provide satisfactory professional and personalized wood-based panel machinery manufacturing and service for the vast majority of wood processing enterprises at home and abroad.Domestic and foreign businessmen are welcome to visit.

For more information, please visit our company website: yihemachinery.en.made-in-china.com

Related Category

Wood Pellet Mill

Woodworking Engraving Machine

Wood Saw Machine

Wood Based Panel Machine

Wood Router

Other Woodworking Machinery

Wood Edge Banding Machine

Wood Press

Wood Sander

Wood Chip Machine

Wood Planer

Wood Lathe

Wood Drilling Machine

Wood Crusher

Woodworking Machinery Parts

Wood Debarker

Carbonization Furnace

Woodworking Composer

Wood Shaving Machine

Mortising Machine

Finger Jointer

Wood Boring Machine

Wood Embossing Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.