High-Precision Indian Wire Cutting Produced by a Chinese Factory in India

ModelWorktable size (mm)Worktable travel (mm)Max. cutting thickness (mm)Processing taperMax. load weight (kg)Main machine weight(kg)DK7720250x320200x2502006°/80mm100800DK7725270x420250x3204006°/80mm2001200DK7732380x600320x4004006°/80mm300140DK7740410x710400x5004006°/8......

Send Inquiry

Product Description

| Model | Worktable size (mm) | Worktable travel (mm) | Max. cutting thickness (mm) | Processing taper | Max. load weight (kg) | Main machine weight(kg) |

| DK7720 | 250x320 | 200x250 | 200 | 6°/80mm | 100 | 800 |

| DK7725 | 270x420 | 250x320 | 400 | 6°/80mm | 200 | 1200 |

| DK7732 | 380x600 | 320x400 | 400 | 6°/80mm | 300 | 140 |

| DK7740 | 410x710 | 400x500 | 400 | 6°/80mm | 450 | 1600 |

| DK7745 | 500x750 | 450x550 | 400 | 6°/80mm | 450 | 1650 |

| DK7755 | 596x880 | 550x650 | 500 | 6°/80mm | 800 | 2500 |

| DK7763 | 790x1260 | 630x1000 | 600 | 6°/80mm | 1000 | 3500 |

| DK7780 | 900x1500 | 800x1200 | 600 | 6°/80mm | 1500 | 5500 |

| DK77100 | 1010x1500 | 1000x1200 | 600 | 6°/80mm | 1500 | 5600 |

| DK77120 | 1300x1900 | 1200x1600 | 600 | 6°/80mm | 4000 | 10000 |

- Optional two-axis or four-axis hybrid stepper motor

2. Four-axis hybrid motor effectively enhance the dynamic response characteristics of large swing machine, to ensure the accuracy of a large taper cutting

3. Spray water to follow the molybdenum wire tilt, in the cutting process to ensure smooth chip removal, is conducive to the stability of the large taper processing

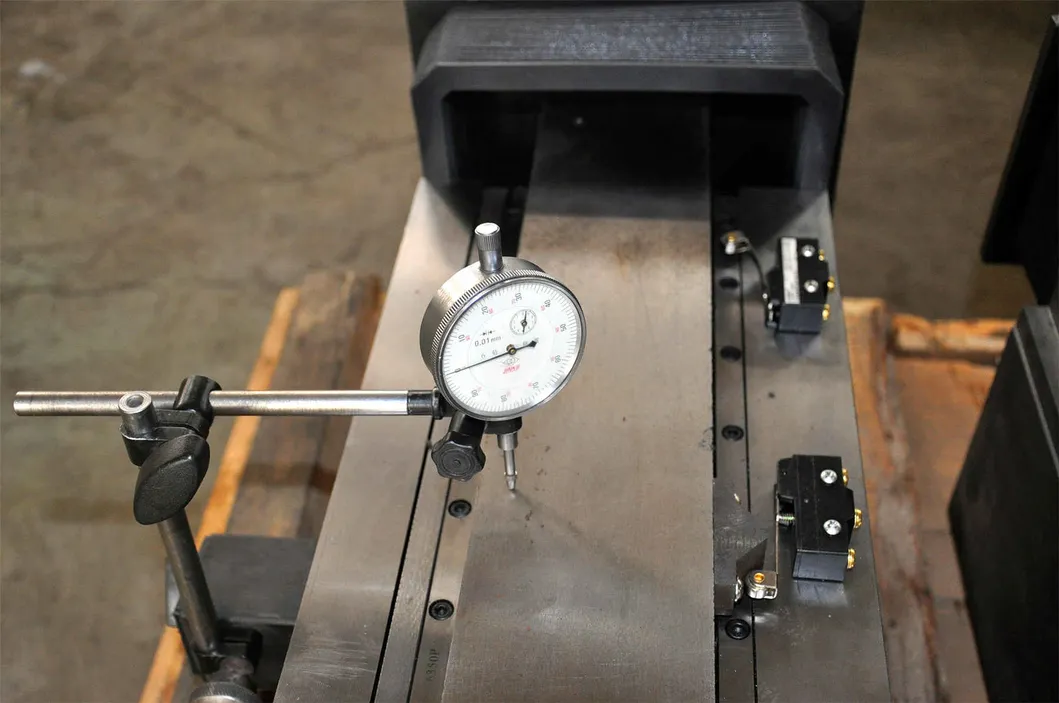

4. Through the machine tool parts of the aging, heat treatment and effective, sophisticated follow-up processing, assembly, making the machine has a good accuracy and accuracy to maintain the characteristics

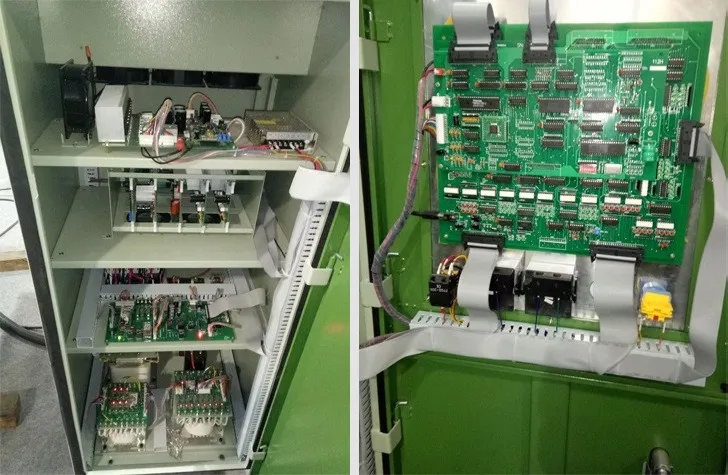

5. Electric control part of the non-power resistance, no transformer, so the cabinet does not heat, all the energy are used for cutting and greatly delay the aging of components, is conducive to long-term rapid cutting

6. Narrow pulse width, high current characteristics of high-frequency power supply, wire conveyor for the smooth characteristics of the machine and the various parts of the fine processing and assembly characteristics to ensure that the cutting of the workpiece surface quality

7. The use of non-stop constant current high frequency voltage cutting process, effectively avoiding the voltage and current negative, which greatly reduces the loss of molybdenum wire, constant current source technology to enhance the utilization of power, reduce power consumption

8. Innovative peak current limiting method and technology, even in the high current cutting, encountered cutting short circuit, due to the peak current is limited, it will not break the wire, thereby significantly reducing the rate of broken wire

9.V-axis optional linear guide, ball screw, improve the quality of taper processing

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q. Could your engineers go to our factory to install the machine and train our workers?

A:Yes, our engineers could go to your factory and assist you.

Q:What is your warranty?

A:One year after shipment ,consumables are not included.

Q: What is your terms of payment ?

A:L/C or T/T before shipment.

Description

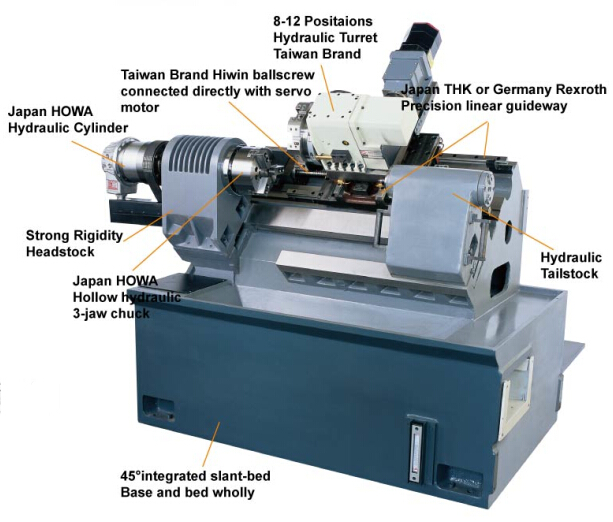

Electrical Discharge Machine(EDM), Die-sinking EDM, also called cavity type EDM or volume EDM, consists of an electrode and workpiece submerged in an insulating liquid such as, more typically, oil or, less frequently, other dielectric fluids. The electrode and workpiece are connected to a suitable power supply. The power supply generates an electrical potential between the two parts. As the electrode approaches the workpiece, dielectric breakdown occurs in the fluid, forming a plasma channel, and a small spark jumps.

These sparks usually strike one at a time because it is very unlikely that different locations in the inter-electrode space have the identical local electrical characteristics which would enable a spark to occur simultaneously in all such locations. These sparks happen in huge numbers at seemingly random locations between the electrode and the workpiece. As the base metal is eroded, and the spark gap subsequently increased, the electrode is lowered automatically by the machine so that the process can continue uninterrupted. Several hundred thousand sparks occur per second, with the actual duty cycle carefully controlled by the setup parameters. These controlling cycles are sometimes known as "on time" and "off time". The on time setting determines the length or duration of the spark. Hence, a longer on time produces a deeper cavity for that spark and all subsequent sparks for that cycle, creating a rougher finish on the workpiece. The reverse is true for a shorter on time. Off time is the period of time that one spark is replaced by another. A longer off time, for example, allows the flushing of dielectric fluid through a nozzle to clean out the eroded debris, thereby avoiding a short circuit. These settings can be maintained in microseconds. The typical part geometry is a complex 3D shape, often with small or odd shaped angles. Vertical, orbital, vectorial, directional, helical, conical, rotational, spin and indexing machining cycles are also used.

Main Features

- Complex shapes that would otherwise be difficult to produce with conventional cutting tools.

- Extremely hard material to very close tolerances.

- Very small work pieces where conventional cutting tools may damage the part from excess cutting tool pressure.

- There is no direct contact between tool and work piece. Therefore delicate sections and weak materials can be machined without any distortion.

- A good surface finish can be obtained.

- very fine holes can be drilled.

Specification

| Items | Unit | 340P |

| X Travel | mm | 450 |

| Y Travel | mm | 350 |

| Z Travel | mm | 210 |

| Cutting Accuracy | " | 45 |

| Max. Electrode Weight | kg | 180 |

| Max. Workpiece Weight | kg | 1200 |

| Max. Workpiece | mm | 1030*650*500 |

| Dielectric Fluid Reservoir | mm | 900*500*350 |

| Max.Electric Current | A | 75 |

| Power Supply | V | AC200V-440V |

| Input Power | KVA | 6 |

| Min. ON TIME | μs | 1 |

| Min. OFF TIME | μs | 1 |

| Max. Working Speed | mm/min | 420 |

| Best Surface Precision | μmRa | 0.02 |

| Min. Electrode Wear Rate | % | <0.3 |

| Machine Unit Dimensions (W x D x H) | mm | 1400*1000*425 |

| Machine Unit Weight | Kg | 1500 |