Home > Products > Plastic Machinery > Blister Machine > High Quality Vacuum Forming Machine (XC46-71/122- BWP )

High Quality Vacuum Forming Machine (XC46-71/122- BWP )

Direct Manufacture Automatic Blister Vacuum Forming MachineXC46-71/122-BWP AUTOMATIC VACUUM FORMING MACHINEUsage:The machine is suitable for making all size packing containers ,in open-type with thin-wall ,by using roll-sheet , under high-speed vacuum suction-forming processing .The products out of ......

Send Inquiry

Product Description

Direct Manufacture Automatic Blister Vacuum Forming Machine

XC46-71/122-BWP AUTOMATIC VACUUM FORMING MACHINE

Usage:

The machine is suitable for making all size packing containers ,in open-type with thin-wall ,by using roll-sheet , under high-speed vacuum suction-forming processing .The products out of this machine can be used for the package of foods .native-products,tourist-goods,textile,medical, toy,cosmetic,electrical elements and daily used hard-ware ,etc .

Sheet fit to the machine

Starch-deposit sheets ,light-deposit sheet ,environment sheet APET ,PETG .Color sheets :PVC,HIPS,PET,PS,PP, EPS, etc.Fiber-coating-sheet.

Structure features

1.The machine combine with mechanical ,pneumatic and electrical integration fully computer control .Touch Screen easy operation.

2.Inverter Feeding Driving ,length stepless adjust ,Feeding accurate, stable and high speed.(Max Feeding Speed 1000mm /per second)

3.Temperature Control system , fully computer intellectual temperature control , short heating time ( only 3 min from 0-400 degree ) ; stable ( not effect by outside voltage and temperature fluctuate is less than 1 degree) ; lower power consumption 15% , longer life of far infrared ray ceramic heater.

4.Heater has deflection over structure ,which could close whole row of the porcelain heaters when the width of sheet is≤580mm.It can reduce power consumption 16%.

5.Heating Temperature control , individual heating control , Touch Screen input , mini-adjustment precision and heating temperature uniformity .

6.Advance feeding with the heating time automatic memory function ,machine could start production from the first feeding .

7.Two-step vacuum ,Two time of up-mould ,Mould Shaking Function ,Mould delay .

8.Up/down Mould electric stroke adjust ,easy to adjust under the mould matched situation .It could improve the accurate of molding and quality of finished production .

9.Back acting plate position motor adjust .

10.Up/down mould match into cushion ,avoid cushion and improve the match speed .

11.Up/down Guiding Leader with self-lubrication bearing couple .stable production and durable structure ,it could assure the high quality of finished products.

12.Heaters with moving-out structure ,could move out under the malfunction situation ,it could save the sheet materials .

13.Cylinder Sheet Loading structure ,easy for workwoman operation .

14. Cutting unit with double clamping cutting function ,could produce Male/Female and various different of products slide cutting .

15.Movement Guide Pole, easily stack .

Technical Components

Technical Parameter

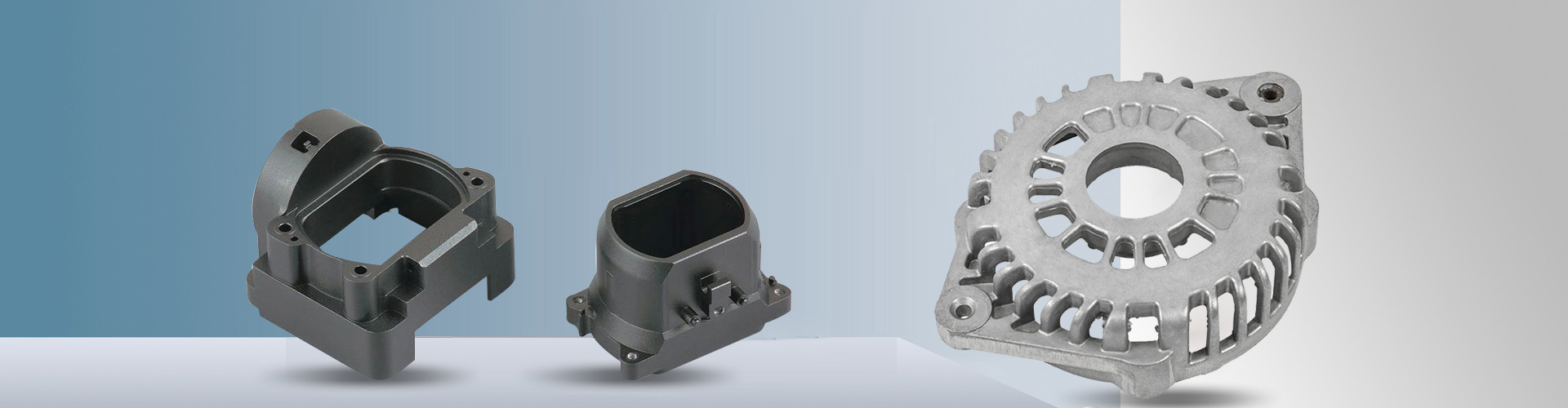

VI,Sample Pictures

VII,Certifications

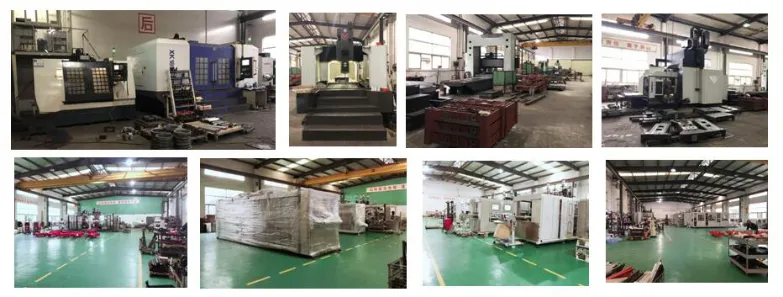

VIII,Workshop Pictures

IX,Package

X,Exhibition

XC46-71/122-BWP AUTOMATIC VACUUM FORMING MACHINE

Usage:

The machine is suitable for making all size packing containers ,in open-type with thin-wall ,by using roll-sheet , under high-speed vacuum suction-forming processing .The products out of this machine can be used for the package of foods .native-products,tourist-goods,textile,medical, toy,cosmetic,electrical elements and daily used hard-ware ,etc .

Sheet fit to the machine

Starch-deposit sheets ,light-deposit sheet ,environment sheet APET ,PETG .Color sheets :PVC,HIPS,PET,PS,PP, EPS, etc.Fiber-coating-sheet.

Structure features

1.The machine combine with mechanical ,pneumatic and electrical integration fully computer control .Touch Screen easy operation.

2.Inverter Feeding Driving ,length stepless adjust ,Feeding accurate, stable and high speed.(Max Feeding Speed 1000mm /per second)

3.Temperature Control system , fully computer intellectual temperature control , short heating time ( only 3 min from 0-400 degree ) ; stable ( not effect by outside voltage and temperature fluctuate is less than 1 degree) ; lower power consumption 15% , longer life of far infrared ray ceramic heater.

4.Heater has deflection over structure ,which could close whole row of the porcelain heaters when the width of sheet is≤580mm.It can reduce power consumption 16%.

5.Heating Temperature control , individual heating control , Touch Screen input , mini-adjustment precision and heating temperature uniformity .

6.Advance feeding with the heating time automatic memory function ,machine could start production from the first feeding .

7.Two-step vacuum ,Two time of up-mould ,Mould Shaking Function ,Mould delay .

8.Up/down Mould electric stroke adjust ,easy to adjust under the mould matched situation .It could improve the accurate of molding and quality of finished production .

9.Back acting plate position motor adjust .

10.Up/down mould match into cushion ,avoid cushion and improve the match speed .

11.Up/down Guiding Leader with self-lubrication bearing couple .stable production and durable structure ,it could assure the high quality of finished products.

12.Heaters with moving-out structure ,could move out under the malfunction situation ,it could save the sheet materials .

13.Cylinder Sheet Loading structure ,easy for workwoman operation .

14. Cutting unit with double clamping cutting function ,could produce Male/Female and various different of products slide cutting .

15.Movement Guide Pole, easily stack .

Technical Components

| Touch Screen Monitor( 10.4 " inch /Color ) | Taiwan Delta |

| PLC | Taiwan Delta |

| Inverter 3.7Kw | Taiwan Delta |

| Encoder | Japan |

| Vacuum Pump | Germany Busch |

| Cylinder | China |

| Pneumatic | Japan SMC & Korea Sanwo |

| Adjust Sprayer | Meiji |

| Fan Blower (4*0.37Kw) | China Manda |

| Contactor | Germany,Siemens |

| Thermo relay | Germany,Siemens |

| Middle relay | Germany, Weidmuller |

| Impulse Solid State Relay | Joint Venture |

| Mold Tray | 430-680mm adjustable water cooling base |

| Heater | 60 Pcs Far Infrared Ray Heaters |

| Upper Heater 60 Zone ( 1 control 1 )Section Adjust , Digital input | |

Technical Parameter

| Suitable Sheet Width(mm) | 460-710 | |

| Thickness(mm) | 0.1-1.2 | |

| Max Roll Sheet (mm) | 600 | |

| Up Mould Stroke (mm) | 400 | |

| Down Mould Stroke(mm) | 300 | |

| Max Forming Area(mm2) | 680×1200 | |

| Max Forming Height Protruding(mm) | 200 | |

| Max Forming Height Concave(mm) | 150 | |

| Capacity (Cycle/min) | 4-12 | |

| Cooling Outlet | Outlet | 4 PCS |

| Spray | 8 PCS | |

| Air Source | Air Vol. (m3/min) | ≥2 |

| Pressure(MPa) | 0.8 | |

| Water Consumption | 4-5 Cube/Hr | |

| Vacuum Pump ( Outlay ) | Busch R5 0100 | |

| Power Supply | 380V/ 220V 50Hz 3Phase 4 line | |

| Heater Power(Kw) | 30 | |

| General Power Max(Kw) | 37 | |

| Dimension(L×W×H)(mm) | 8070×1656×2425 | |

| Weight(kg) | 4700 | |

VI,Sample Pictures

VII,Certifications

VIII,Workshop Pictures

IX,Package

X,Exhibition

Related Category

Plastic Extruder

Injection Molding Machine

Blow Molding Machine

Plastic Recycling Machine

Plastic Pipe Machinery

Film Blowing Machine

Plastic Crusher

Plastic Granulator

Foam Machinery

Thermoforming Machine

Plastic Plate Machinery

Profile Production Line

Bottle Blowing Machine

Other Plastic Machinery

Plastic Machinery Parts

Blister Machine

Plastic Drawing Machine

Rotational Molding Machine

Plastic Mixer

Plastic Rolling Machinery

Plastic Loader

Plastic Laminating Machine

Plastic Drying Machine

Plastic Haul-Off Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.