Home > Products > Plastic Machinery > Blister Machine > High Speed Cake Box Forming Machine (XC46-71/122- BWP )

High Speed Cake Box Forming Machine (XC46-71/122- BWP )

I,UsageThis machine is mainly adapted to a variety of plastic reel sheet vacuum forming various open thin-walled containers for food, souvenirs, travel goods, textiles, decorations, cosmetics, medical supplies, in medicine, children toys, electrical and electronic components, hardware and other good......

Send Inquiry

Product Description

I,Usage

This machine is mainly adapted to a variety of plastic reel sheet vacuum forming various open thin-walled containers for food, souvenirs, travel goods, textiles, decorations, cosmetics, medical supplies, in medicine, children toys, electrical and electronic components, hardware and other goods producing all kinds of packaging products.

II,Available sheet

1. Starch degradation sheet

2. Optical degradation sheet

3. Green sheet: APET, PETG

4. Various colors sheet: PVC, HIPS, PET, PS, PP, EPS, etc.

III,Features

1. Mechanical, pneumatic and electrical integration. Each action program controlled by the PLC. Touch-screen operation, simple and convenient.

2. Frequency sheet feeding, stepless adjustment of length, speed accuracy and stability. (Max. Speed 1000mm /s)

3. Automatically compensates for temperature control system using intelligent control, fast heating (from 0-400 degrees takes 5 minutes), stable (without external voltage impact, temperature fluctuations of not more than 1 degree), low energy consumption (15% saving), fever long life and other advantages of brick.

4. Electric furnace with a bias structure, when the sheet width of less than 580mm, closed electric furnace heat tiles while the entire row can reduce energy consumption by 16%.

5. Furnaces partition using gear switch (divided into ten stalls), a control of a regulator, easy to adjust the temperature uniformity, easy to use, simple.

6. Early feeding with the heating time automatic memory function, since the first edition of the machine can enter the normal working condition.

7. Vacuum in two steps,forming mold adjusted twice,shock release, delay vacuum

8. Two directions adjustable up and down stroke, in which the mold clamping direction electric adjustment, can be adjusted in the mold on the state (and lower) mold height position, and convenient.

9. Electric gate position after adjustment.

10. Under the direction of the mold clamping readily into the buffer, to improve the speed of the mold, to avoid shock.

11. Upper and lower die sets bushing using mosaic solid lubricating bearings, so that the upper and lower mold under smooth and accurate movement on stage, will help improve the quality of products.

12. Automatic electric furnace removed device is disconnected in the middle of the sheet can be produced at any time without stopping and starting, do not waste sheets.

13. Mechanical reel device, reduce labor intensity.

14. Double action cutting mechanism plywood, electric slicing methods to meet overcast, sub-version of the male die cutting products of any shape.

15. Movement Guide column, so that products stack neatly.

IV,Technical Parameters

| Parameter | XC46-71/122A-WP(mode No.) | |

| Available sheet width (mm) | 460-710 | |

| Available sheet thickness (mm) | 0.1-1.2 | |

| Max.dia.of sheet roll (mm) | 600 | |

| Up mold stroke (mm) | 400 | |

| Down mold stroke (mm) | 300 | |

| Max. forming area (mm2) | 680 × 1200 | |

| Max. forming height (mm) | 200(male mold) | |

| Max. forming height (mm) | 150 (female mold) | |

| Capacity (times / min) | 4-10 | |

| Product Shaping&Cooling | Air vent qty. | 4pcs |

| Spray nozzle qty. | 8pcs | |

| Air supply (m3/min) | ≥ 2 | |

| Pressure (MPa) | 0.8 | |

| Water consumption | 4-5 Cube / Hour | |

| Vacuum pump (external) | Busch R5 0100 | |

| Power supply | 3-phase 4-wire 380V / 220V 50Hz | |

| Heating power (Kw) | 54 | |

| Max. power of whole machine (Kw) | 61.23 | |

| Dimensions (L × W × H)(mm) | 8070 × 1656 × 2425 | |

| Weight of whole machine (Kgs) | 4700 | |

V,Technical configuration

| HMI 5.7 inches color | Taiwan Delta |

| PLC 48 | Taiwan Delta |

| Inverter 2.2Kw | Taiwan Delta |

| Encoder 1024 | Taiwan Delta |

| Vacuum pump | Busch |

| Cylinder (upper and lower molds adopt thick-rod cylinder) | Zhicheng |

| Pneumatic component | Korea Sanwo |

| Adjustable spray gun | Meiji |

| Fan | Manda |

| AC contactor | Germany Siemens |

| Heating relay | Germany Siemens |

| Relay | Omron |

| Pulsed solid-state relay | joint venture brand |

| Heating furnance | 120 pcs of far infrared ceramic heaters,up&down heating furnances, zoning one-one control(120zones) |

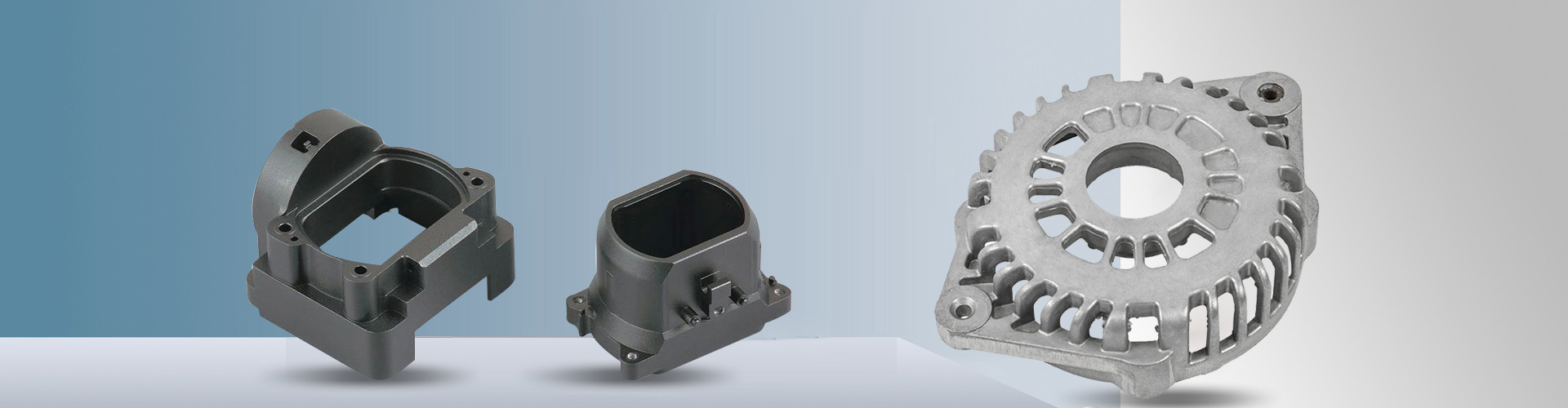

VI,Sample Picture

VII,Certification

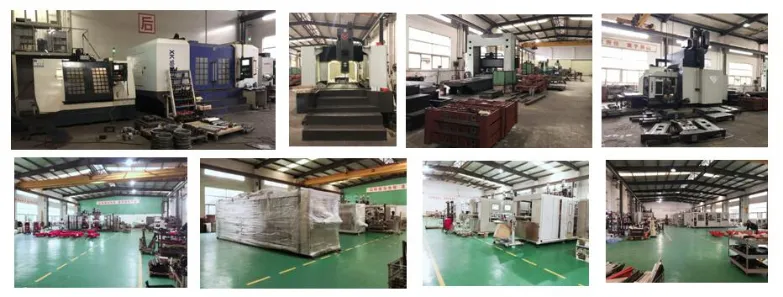

VIII,Workshop Pictures

IX,Package

X,Exhibition

Related Category

Plastic Extruder

Injection Molding Machine

Blow Molding Machine

Plastic Recycling Machine

Plastic Pipe Machinery

Film Blowing Machine

Plastic Crusher

Plastic Granulator

Foam Machinery

Thermoforming Machine

Plastic Plate Machinery

Profile Production Line

Bottle Blowing Machine

Other Plastic Machinery

Plastic Machinery Parts

Blister Machine

Plastic Drawing Machine

Rotational Molding Machine

Plastic Mixer

Plastic Rolling Machinery

Plastic Loader

Plastic Laminating Machine

Plastic Drying Machine

Plastic Haul-Off Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.