Home > Products > Woodworking Machinery > Other Woodworking Machinery > 2-20tph Log Branch Pallet Wooden Box Chipping Drum Type Wood Chipper Machine

2-20tph Log Branch Pallet Wooden Box Chipping Drum Type Wood Chipper Machine

Wood chips are required as the starting material in the wood processing line, which places wood chipper in an indispensable role in the wood processing industry. With the high strength steel, double feeding system, the drum wood chipper is mainly suitable for processing undersized logs, wood residue......

Send Inquiry

Product Description

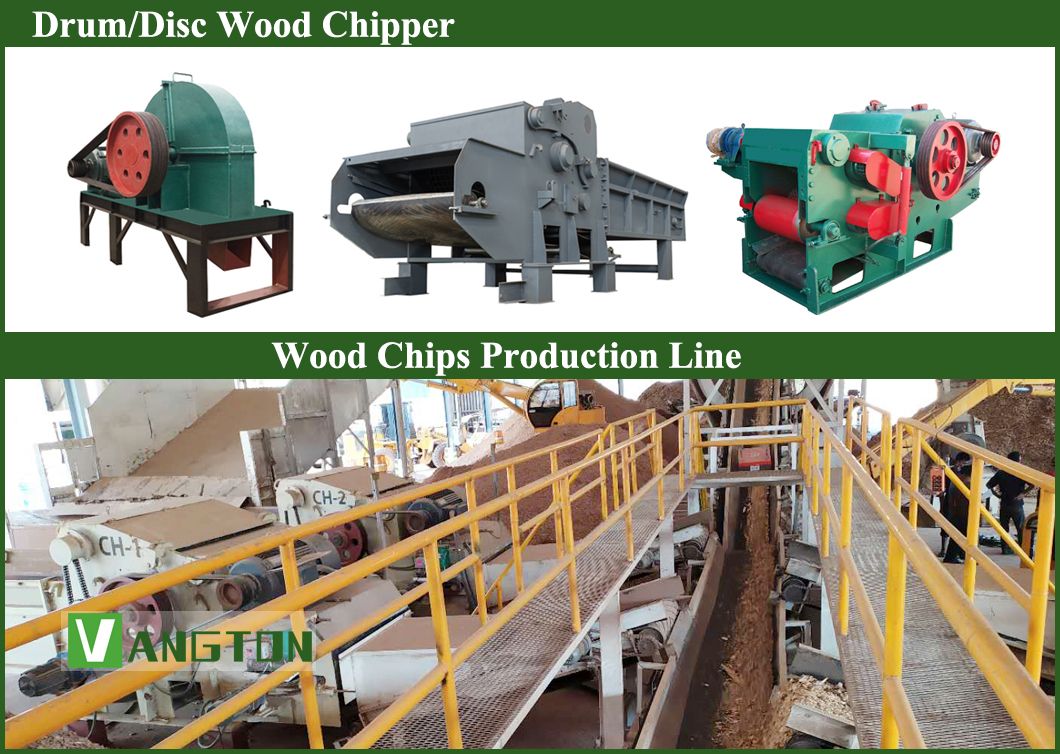

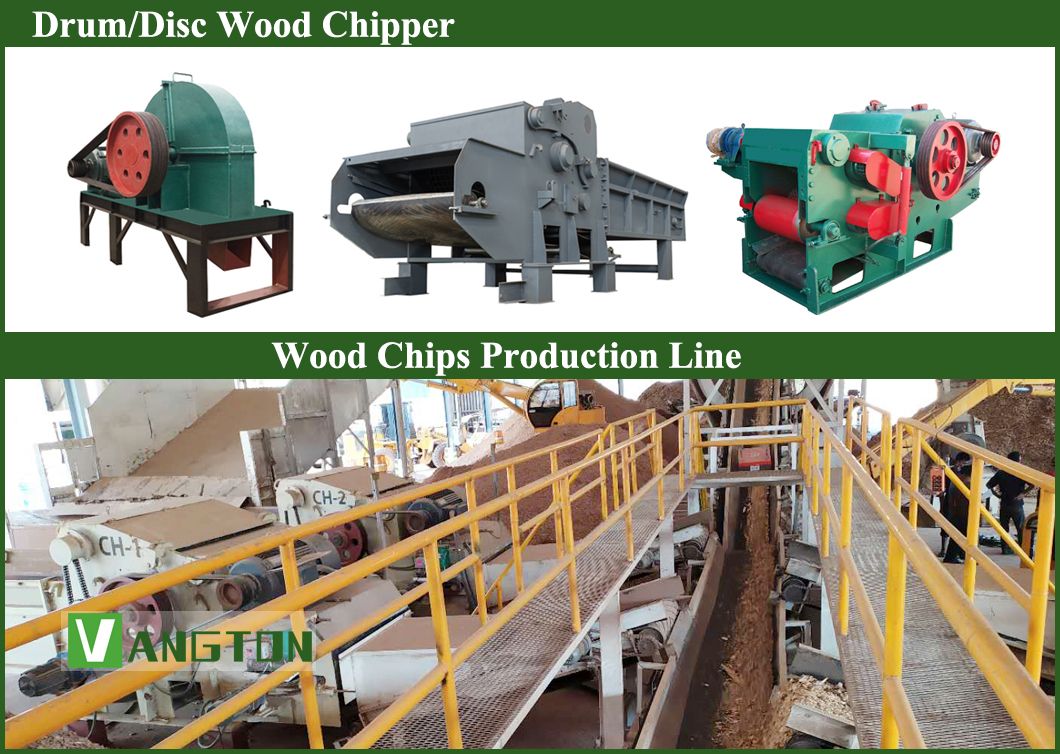

Wood chips are required as the starting material in the wood processing line, which places wood chipper in an indispensable role in the wood processing industry. With the high strength steel, double feeding system, the drum wood chipper is mainly suitable for processing undersized logs, wood residue (twigs, branches) and fiber agro waste such as hemp pole, reed stalks, bamboo etc. Distinct design, compact structure and simple operation make wood chipping machine enjoy popularity during wood processing industry and biofuel processing industry.

The wide variety in sizes and designs of drum chippers guarantees an individual and customized solution for optimal operation in every field of application. With the extensive product range, the drum chippers can be extended and combined to complete and fully automatic processing systems.

Features of Drum Wood Chipper

1.Compact structure, simple operation, the drum wood chipper has a wide application for wood materials chipping and biomass materials processing.

2. Adopting the double roller feeding system, the drum wood chipper has a higher efficiency than the common one.

3. The chipper body is made of high strength steel, firm, shock-resistant, with less noise.

4. A series of screen for choice, the drum wood chipper can process wood chips with a variety of size and thickness for different requirements.

5. Special design and reliable blades layout, the drum wood chipper works more efficiently. The wood chips is of even length and uniform thickness.

6. With the hydraulic buffer system, the maintenance of the chipping machine is simple.

Applications of Drum Wood Chipper

With advanced structure and special blades layout, the drum wood chipper is technically suitable for undersized logs processing. In fact, the drum wood chipper can process a variety of materials. The common raw materials for the drum wood chipper are undersized wood logs, wood branches, wood barks, waste board.

Technical specification

The feeding of the wood chips is effected by specially serrated feed rolls (they are surface treated and guarantee a long service life). The feed rolls are powered by high-performance slip-on bevel gears.

The adjustment of the chipping blades is realized outside the machine with a blade alignment gauge. The counter blade can be removed quickly and easily at the side of the machine. The blade can be used and resharpened quadliterally. The elevated post-chipping screen and the rigid blade bar ensure homogenous wood chips.

OUR PROJECTS

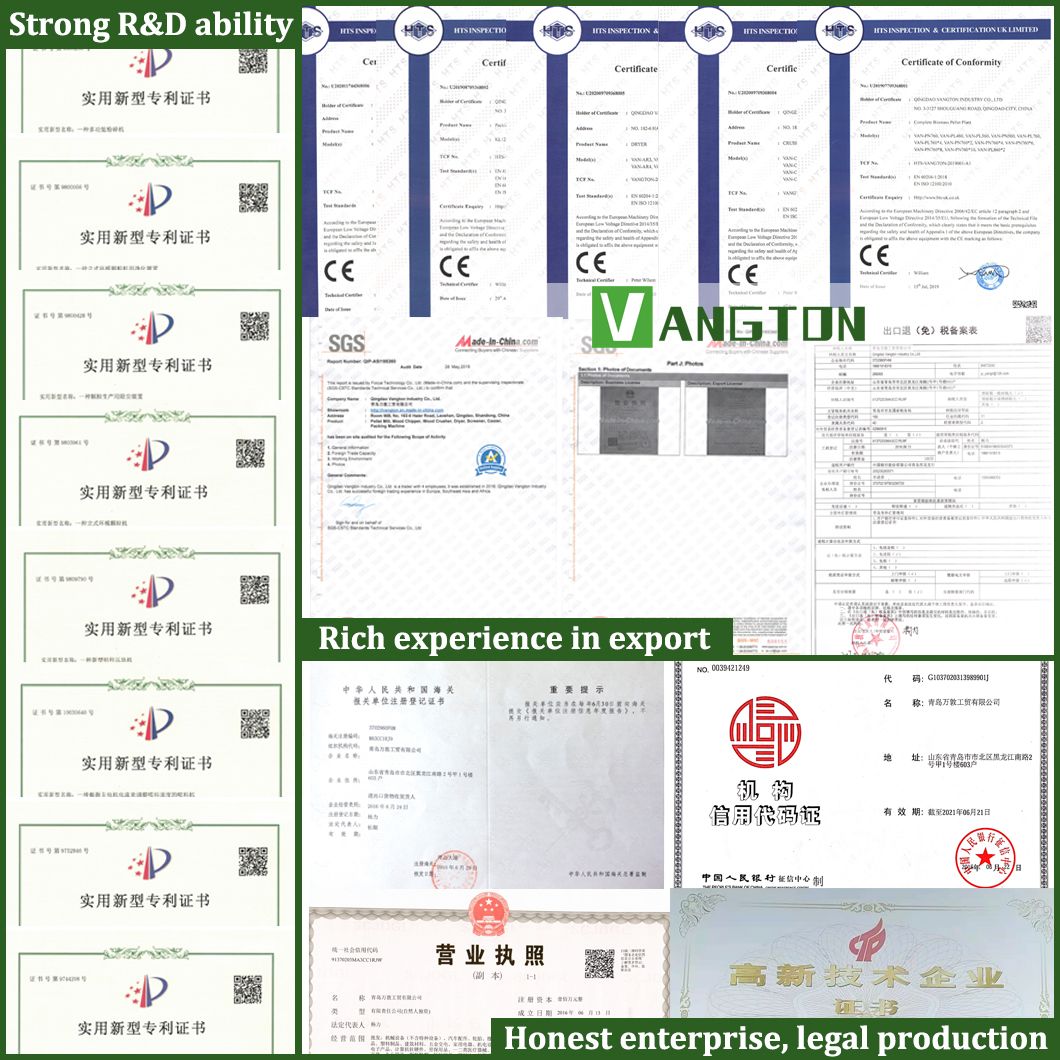

OUR CERTIFICATE

THE CLIENTS WITH US

OUR SERVIC

Pre-sale service

1.Our professional and experienced engineer team helps every client to find his most suitable equipment or chose of plant.

2. Any kind of legal logo printing or design are available.

3.Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

After you choose:

1. We will make drawing and show you how the pant looks.

2. Every equipment will be checked carefully before packing. Video on machine testing is available.

3. Email you the tracking no., and help to chase the container until it arrives you.

After-sale service

1.We are very glad that customers give us some suggestion for price and products.

2.If you have any question,please contact us freely by E-mail or Telephone.

FAQ

Q. what is your payment term?

A: T/T 30% down payment, balance to be paid before shipment.

Q: what is your main market?

A: South America, Eastern Europe, Southeast Asia, Africa, Oceania, Eastern Asia

Q: what is your producing time?

A: Producing time depends on that machines you ordered. Usually takes 45 days.

Q: what documents you can offer?

A: We can offer invoice, packing list, contract, instructions, customs declaration, certificate of origin, CE. If client need other documents, specifications, please confirm with service staff.

Q: If equipments have some quality problem, how would you deal with?

A: We will responsible for all the quality problems. We will check the machine to get the problem. If need parts, will send them to you.

Q: how to install the equipments?

A: We send 1-2 engineer (100usd/person/day) to the local plant for helping install and commissioning equipments. To save time, our service stuff will tell you what to prepare in advance. We can also teach the workers to how to use the machines and how to make the products better.

| Model | Capacity | Knife qty | Power | Feeding port | Maxi log diameter | Chips length | Weight | |

| GWC215 | ≈3 t/h | 2/3 pcs | 45kw | 160x400 mm | 160mm | 20-35 mm | 2.9t | |

| GWC216 | ≈5 t/h | 2/3 pcs | 55kw | 230x540 mm | 200mm | 20-35 mm | 4t | |

| GWC218 | ≈8 t/h | 3/4/5 pcs | 110kw | 300x680 mm | 300mm | 20-35 mm | 7.2t | |

| Drum Disc Wood Chipper Shredder Machine is mainly suitable for processing undersized logs, wood residue (twigs, branches) and fiber agro waste such as hemp pole, reed stalks, bamboo etc. | ||||||||

| Model | 1250 | 1400 | 1600 | |||||

| Feeding port size (mm) | 1250*600 | 1400*600 | 1600*800 | |||||

| Quantity of hammers (pc) | 24 | 24 | 32 | |||||

| Speed (rpm) | 880 | 880 | 900 | |||||

| Max size of log (mm) | 300-400 | 300-400 | 500 | |||||

| Chip size (mm) | 20-30 | 20-30 | 20-50 | |||||

| Capcacity (t/h) | 8-10 | 10-15 | 20-25t | |||||

| Motor (kw) | 132 | 160 | 220 | |||||

| Feed suspension variable frequency motor (kw) | 5.5 | 7.5 | 15 | |||||

| Chain plate feeding variable frequency motor (kw) | 7.5 | 11 | 18.5 | |||||

| Solenoid valve integrated oil pump motor power (kw) | 3 | 3 | 3 | |||||

| Primary conveyor motor power (kw) | 5.5 | 5.5 | 5.5 | |||||

The wide variety in sizes and designs of drum chippers guarantees an individual and customized solution for optimal operation in every field of application. With the extensive product range, the drum chippers can be extended and combined to complete and fully automatic processing systems.

Features of Drum Wood Chipper

1.Compact structure, simple operation, the drum wood chipper has a wide application for wood materials chipping and biomass materials processing.

2. Adopting the double roller feeding system, the drum wood chipper has a higher efficiency than the common one.

3. The chipper body is made of high strength steel, firm, shock-resistant, with less noise.

4. A series of screen for choice, the drum wood chipper can process wood chips with a variety of size and thickness for different requirements.

5. Special design and reliable blades layout, the drum wood chipper works more efficiently. The wood chips is of even length and uniform thickness.

6. With the hydraulic buffer system, the maintenance of the chipping machine is simple.

Applications of Drum Wood Chipper

With advanced structure and special blades layout, the drum wood chipper is technically suitable for undersized logs processing. In fact, the drum wood chipper can process a variety of materials. The common raw materials for the drum wood chipper are undersized wood logs, wood branches, wood barks, waste board.

Technical specification

The feeding of the wood chips is effected by specially serrated feed rolls (they are surface treated and guarantee a long service life). The feed rolls are powered by high-performance slip-on bevel gears.

The adjustment of the chipping blades is realized outside the machine with a blade alignment gauge. The counter blade can be removed quickly and easily at the side of the machine. The blade can be used and resharpened quadliterally. The elevated post-chipping screen and the rigid blade bar ensure homogenous wood chips.

OUR PROJECTS

OUR CERTIFICATE

THE CLIENTS WITH US

OUR SERVIC

Pre-sale service

1.Our professional and experienced engineer team helps every client to find his most suitable equipment or chose of plant.

2. Any kind of legal logo printing or design are available.

3.Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

After you choose:

1. We will make drawing and show you how the pant looks.

2. Every equipment will be checked carefully before packing. Video on machine testing is available.

3. Email you the tracking no., and help to chase the container until it arrives you.

After-sale service

1.We are very glad that customers give us some suggestion for price and products.

2.If you have any question,please contact us freely by E-mail or Telephone.

FAQ

Q. what is your payment term?

A: T/T 30% down payment, balance to be paid before shipment.

Q: what is your main market?

A: South America, Eastern Europe, Southeast Asia, Africa, Oceania, Eastern Asia

Q: what is your producing time?

A: Producing time depends on that machines you ordered. Usually takes 45 days.

Q: what documents you can offer?

A: We can offer invoice, packing list, contract, instructions, customs declaration, certificate of origin, CE. If client need other documents, specifications, please confirm with service staff.

Q: If equipments have some quality problem, how would you deal with?

A: We will responsible for all the quality problems. We will check the machine to get the problem. If need parts, will send them to you.

Q: how to install the equipments?

A: We send 1-2 engineer (100usd/person/day) to the local plant for helping install and commissioning equipments. To save time, our service stuff will tell you what to prepare in advance. We can also teach the workers to how to use the machines and how to make the products better.

Related Category

Wood Pellet Mill

Woodworking Engraving Machine

Wood Saw Machine

Wood Based Panel Machine

Wood Router

Other Woodworking Machinery

Wood Edge Banding Machine

Wood Press

Wood Sander

Wood Chip Machine

Wood Planer

Wood Lathe

Wood Drilling Machine

Wood Crusher

Woodworking Machinery Parts

Wood Debarker

Carbonization Furnace

Woodworking Composer

Wood Shaving Machine

Mortising Machine

Finger Jointer

Wood Boring Machine

Wood Embossing Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.